-

CN

-

Service Hotline

+8618129931046 Mr. Liao

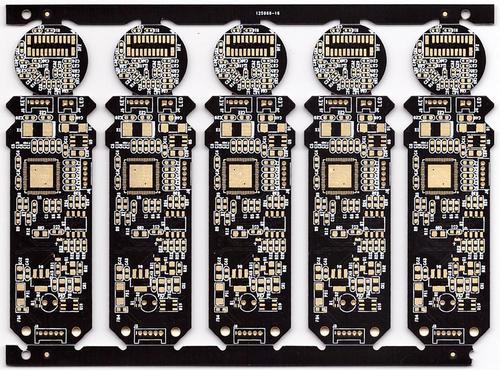

Custom Control Board PCBA refers to the personalized design and manufacturing of Printed Circuit Board Assemblies tailored to specific control system requirements—such as industrial equipment controllers, smart home control panels, automotive electronic control units (ECUs), and medical device c

Nov 18, 2025

Nov 18, 2025

1

1

PCBA power device layout is a specialized design process focused on positioning high-power components (e.g., IGBTs, MOSFETs, voltage regulators, rectifiers) to ensure efficient heat dissipation, minimal power loss, and stable electrical performance. Unlike standard component layout (which priori

Nov 15, 2025

Nov 15, 2025

1

1

Resistor and capacitor selection is a foundational step in PCBA design, directly impacting circuit performance, reliability, and cost-effectiveness. Unlike generic component choices, this process requires matching electrical parameters to the circuit’s functional needs—while considering environmenta

Nov 14, 2025

Nov 14, 2025

1

1

Power Control PCBA is a critical circuit board assembly designed to regulate, distribute, and protect electrical power in a wide range of electronic systems—from consumer devices (e.g., laptops, smartphones) to industrial equipment (e.g., factory machinery, medical devices). Unlike general-purpose P

Nov 13, 2025

Nov 13, 2025

1

1

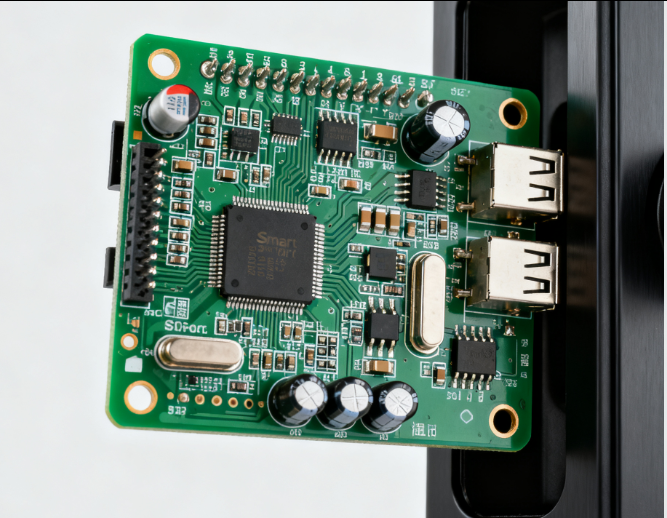

Smart Lock PCBA is the core control unit of smart door locks, integrating hardware and software to enable secure, convenient access management—replacing traditional mechanical keys with digital authentication methods like fingerprint recognition, password input, NFC, or smartphone app control. Unlik

Nov 12, 2025

Nov 12, 2025

1

1

Drone flight control PCBA (Printed Circuit Board Assembly) is the core "brain" of a drone, integrating hardware and software to manage flight stability, navigation, and motor control. Unlike standard consumer electronics PCBs, this specialized assembly must withstand harsh aerial conditions—includin

Nov 11, 2025

Nov 11, 2025

1

1