-

CN

-

Service Hotline

+8618129931046 Mr. Liao

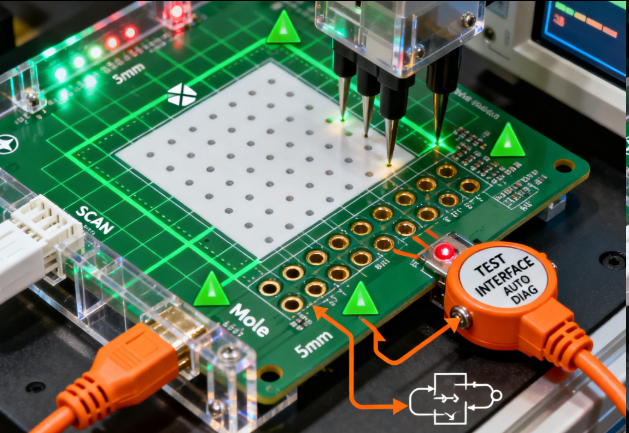

Testability-Oriented PCBA Design (Design for Testability, DFT) is a design approach that integrates features to enable efficient, accurate testing of printed circuit board assemblies—identifying manufacturing defects (e.g., open circuits, short circuits, wrong components) and functional issues early

Nov 27, 2025

Nov 27, 2025

1

1

Cost-Optimized PCBA Design is a design strategy that reduces the total cost of printed circuit board assemblies—including material, manufacturing, and lifecycle costs—without compromising performance, reliability, or functionality. Unlike designs that prioritize performance over cost, cost-optimized

Nov 27, 2025

Nov 27, 2025

1

1

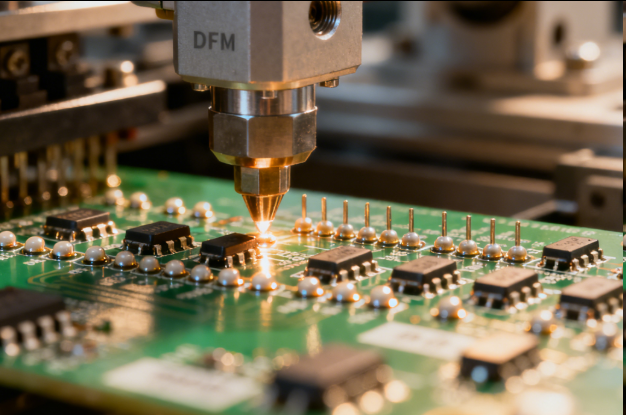

Manufacturability-Oriented PCBA Design (also known as Design for Manufacturability, DFM) is a design approach that optimizes printed circuit board assemblies to align with mass production processes, minimizing manufacturing defects, reducing assembly time, and ensuring consistency across large p

Nov 27, 2025

Nov 27, 2025

1

1

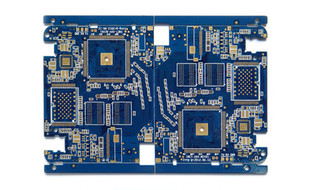

PCBA small-batch trial production refers to the low-volume manufacturing process of Printed Circuit Board Assemblies (PCBAs) — typically ranging from 10 to 500 units — conducted before mass production. This stage is critical for verifying design feasibility, identifying potential issues, and opt

Nov 21, 2025

Nov 21, 2025

1

1

Automotive electronics PCBA assembly focuses on manufacturing high-reliability Printed Circuit Board Assemblies for vehicle-mounted electronic systems—such as engine control units (ECUs), infotainment systems, advanced driver-assistance systems (ADAS), battery management systems (BMS) for electric v

Nov 20, 2025

Nov 20, 2025

1

1

Smart Home PCBA manufacturing focuses on producing cost-effective, low-power, and connectivity-enabled Printed Circuit Board Assemblies for smart home devices—such as smart thermostats, smart lights, security cameras, smart locks, and voice-controlled assistants. Unlike industrial or automotive PCBA

Nov 19, 2025

Nov 19, 2025

1

1