-

CN

-

Service Hotline

+8618129931046 Mr. Liao

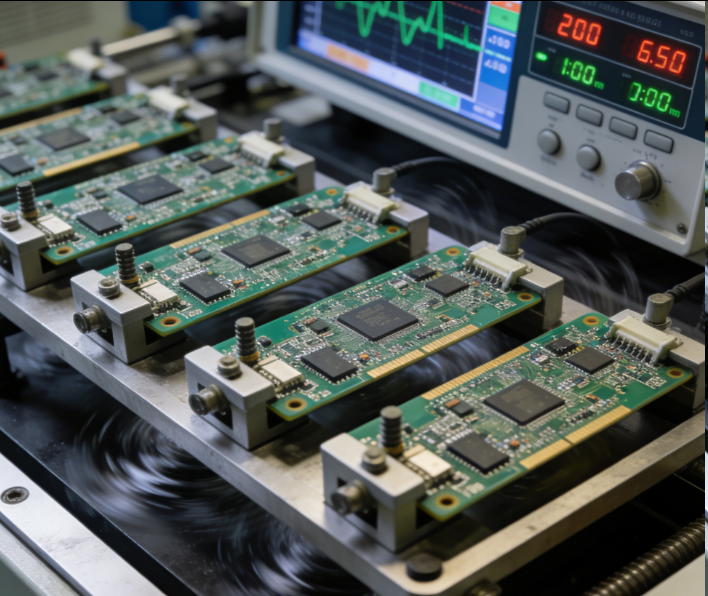

Industrial Internet of Things (IIoT) gateways serve as the crucial bridge between various industrial devices, sensors, and the cloud, enabling seamless data communication and management across the industrial network. The PCB boards designed for IIoT gateways are engineered with high - end capabiliti

Dec 30, 2025

Dec 30, 2025

1

1

PCB Mechanical Testing is a set of standardized evaluations designed to assess a printed circuit board’s ability to withstand physical stress, deformation, and environmental wear—critical for ensuring reliability in applications where PCBs face mechanical forces (e.g., vibration in automotive, bendi

Dec 27, 2025

Dec 27, 2025

1

1

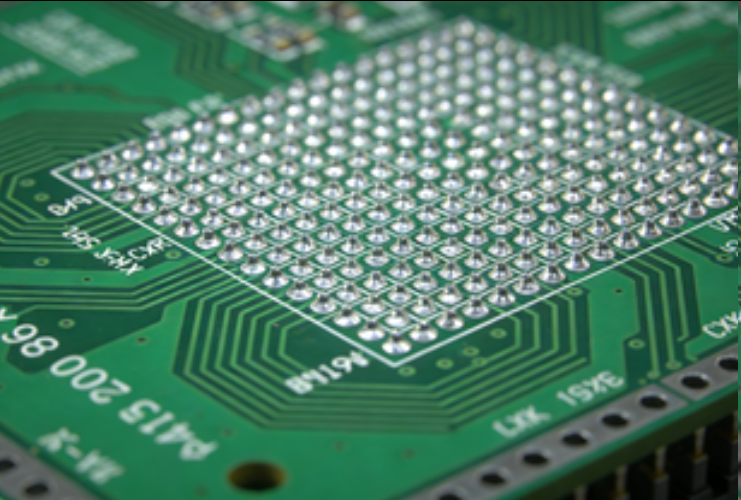

Rigid PCBs (Rigid Printed Circuit Boards) are circuit boards with a rigid, inflexible substrate—typically made of FR-4 (fiberglass-reinforced epoxy resin), ceramic, or metal-core materials—designed to maintain their shape in fixed electronic assemblies. Unlike flexible PCBs (which bend to fit tight

Dec 26, 2025

Dec 26, 2025

1

1

EV PCBs (Electric Vehicle Printed Circuit Boards) are high-performance, durable circuit boards tailored to the unique demands of electric vehicles—powering critical systems like battery management, motor control, infotainment, and ADAS (Advanced Driver Assistance Systems). Unlike consumer electronic

Dec 25, 2025

Dec 25, 2025

1

1

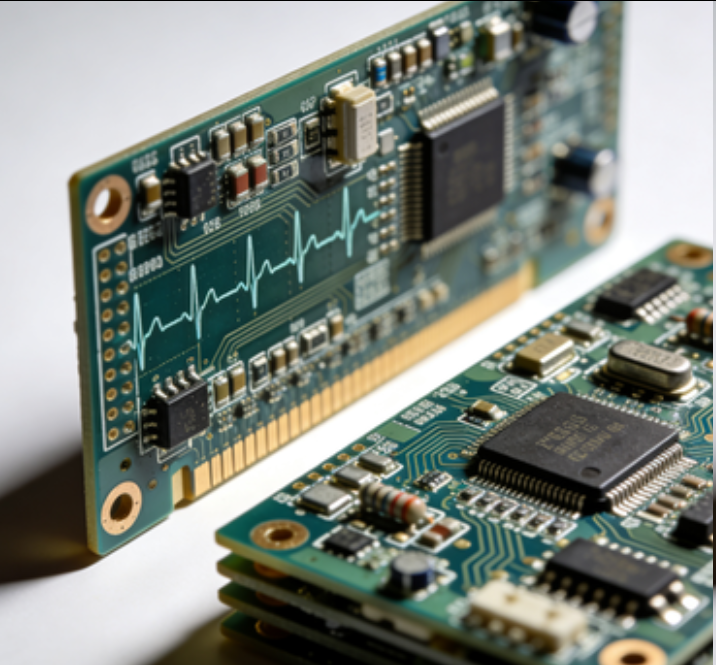

Electrocardiogram (ECG) machines are essential medical devices that record the electrical activity of the heart, providing crucial diagnostic information for healthcare professionals. To ensure accurate and reliable operation, ECG machines rely on specialized printed circuit boards (PCBs) that are m

Dec 24, 2025

Dec 24, 2025

1

1

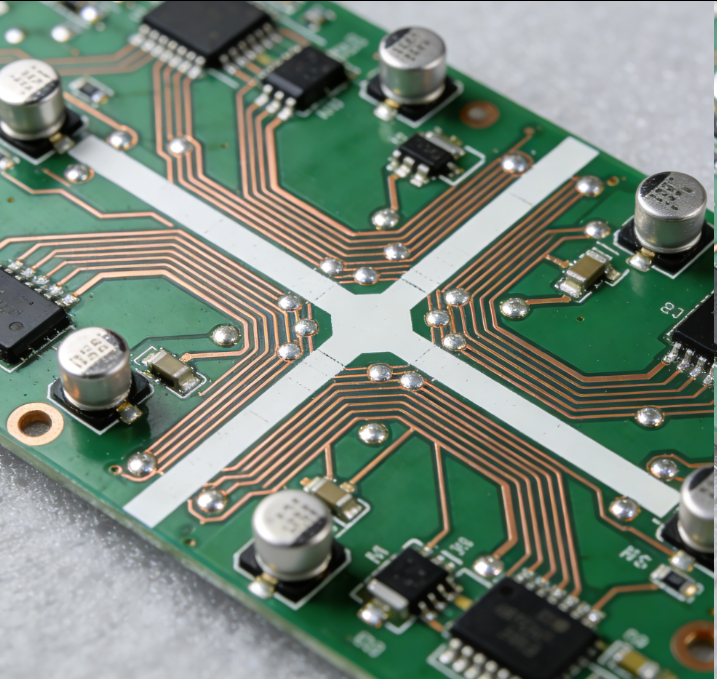

Hall sensors, which operate based on the Hall effect to detect magnetic fields, require specialized printed circuit boards (PCBs) to ensure optimal performance and reliable operation. A dedicated PCB board for Hall sensors is meticulously designed to meet the unique electrical, mechanical, and envir

Dec 23, 2025

Dec 23, 2025

1

1