-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-11-12 Views:1

Smart Lock PCBA is the core control unit of smart door locks, integrating hardware and software to enable secure, convenient access management—replacing traditional mechanical keys with digital authentication methods like fingerprint recognition, password input, NFC, or smartphone app control. Unlike standard mechanical lock components, this specialized PCBA must prioritize security (to prevent unauthorized access), durability (to withstand daily use and environmental factors like temperature changes or humidity), and low power consumption (to support battery operation for 6–12 months). Its primary role is to verify user identities, control the lock’s motor to open/close the bolt, and log access records for monitoring.

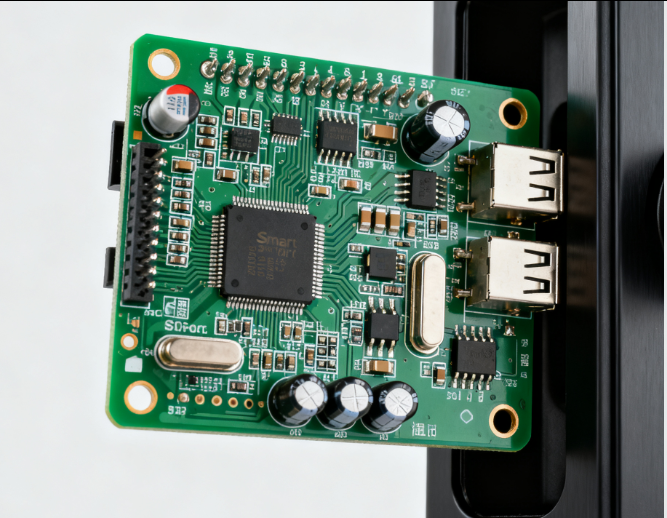

The technical design of Smart Lock PCBA centers on security and multi-factor authentication. Key components include a low-power MCU (e.g., STM32L0 series, Microchip PIC18F series) with built-in encryption modules (AES-256, RSA) to protect user data (e.g., fingerprint templates, access codes) from hacking. It integrates biometric sensors (fingerprint scanners with 500+ DPI resolution for high accuracy, or facial recognition modules for contactless access) and input interfaces (touchpads for passwords, NFC readers for access cards). A motor driver IC (e.g., TI DRV8825) controls the lock’s servo or stepper motor, ensuring smooth, reliable bolt movement. Communication modules (BLE 5.0 or Wi-Fi) enable remote control via smartphone apps—users can unlock doors for guests remotely, receive real-time access alerts, or check battery levels.

Power management and security enhancements are critical design focuses. The PCBA supports dual power sources: primary batteries (4×AA or 2×Li-ion) for daily use and a micro-USB emergency port for low-battery situations. Low-power sleep modes reduce current draw to microamps (μA) when idle, extending battery life. Security features include anti-tamper detection (sensors that trigger alarms if the lock is forced open), fake fingerprint rejection (via live fingerprint detection technology), and brute-force protection (locking the system after multiple wrong password attempts). The PCB uses flame-retardant materials (FR-4 V-0) and conformal coating to resist moisture, dust, and corrosion—essential for locks installed outdoors or in humid environments.

In practical applications, Smart Lock PCBA supports diverse use cases. For residential use, it enables keyless entry for families, with temporary access codes for cleaners or Airbnb guests. For commercial buildings, it integrates with access control systems to manage employee entry (e.g., restricting access to specific floors or times). Some advanced models add IoT connectivity, allowing integration with smart home systems (e.g., unlocking the door automatically when a user’s smartphone is nearby, or triggering lights to turn on after entry). For lock manufacturers, this PCBA is the key to differentiating products in a competitive market—its security features and user-friendly design directly impact consumer trust and satisfaction.