-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Dec 03, 2025

Dec 03, 2025

1

1

With the continuous development of science and technology, PCB board industry is also moving forward, technology upgrading has become a key element of the development of the industry...

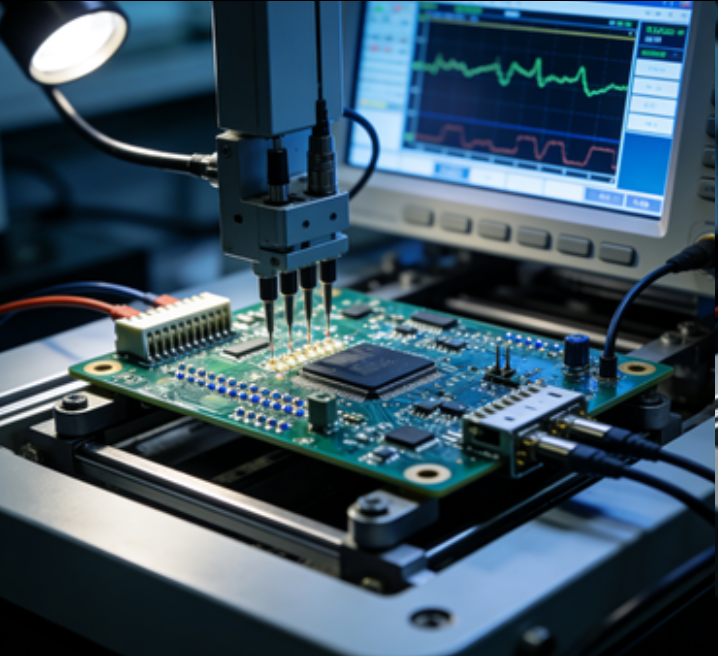

PCBA (Printed Circuit Board Assembly) electrical performance testing ensures that assembled boards meet functional specifications by verifying signal integrity, power distribution, and component behavior. Key tests include in-circuit testing (ICT), flying probe testing, and functional testing. ICT u

Dec 13, 2025

Dec 13, 2025

1

1

Printed circuit board (PCB) routing plays a crucial role in high-speed circuits, but it is often one of the final steps in the circuit design process. There are many aspects to high-speed PCB routing, and extensive literature has been written on the subject. This article mainly explores the routing

Dec 13, 2025

Dec 13, 2025

1

1

PCBA Environmental Testing is a specialized reliability evaluation process that exposes Printed Circuit Board Assemblies (PCBAs) to simulated real-world environmental conditions—such as extreme temperatures, humidity, vibration, shock, and chemical exposure—to validate their performance and durabili

Dec 12, 2025

Dec 12, 2025

1

1

In the electronics manufacturing industry, the production qualifications for PCBA (Printed Circuit Board Assembly) are critical for ensuring product quality, safety, and compliance. A PCBA manufacturer with comprehensive production qualifications typically means it has undergone rigorous industry ce

Dec 12, 2025

Dec 12, 2025

1

1

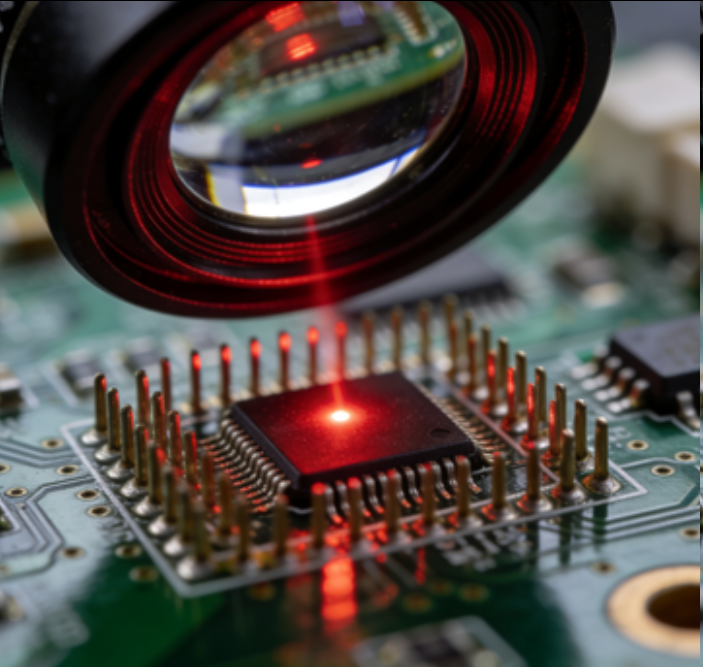

PCBA Automated Optical Inspection (AOI) is an advanced non-contact testing technology designed to detect defects in Printed Circuit Board Assemblies (PCBAs) during the electronics manufacturing process. Unlike manual visual inspection (MVI), which relies on human eyes and is prone to error, AOI uses

Dec 11, 2025

Dec 11, 2025

1

1

In the electronics manufacturing industry, PCBA (Printed Circuit Board Assembly) production qualifications are crucial for ensuring product quality, safety, and compliance. A PCBA manufacturer with comprehensive production qualifications typically signifies that it has undergone rigorous industry ce

Dec 11, 2025

Dec 11, 2025

1

1