-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-12-13 Views:1

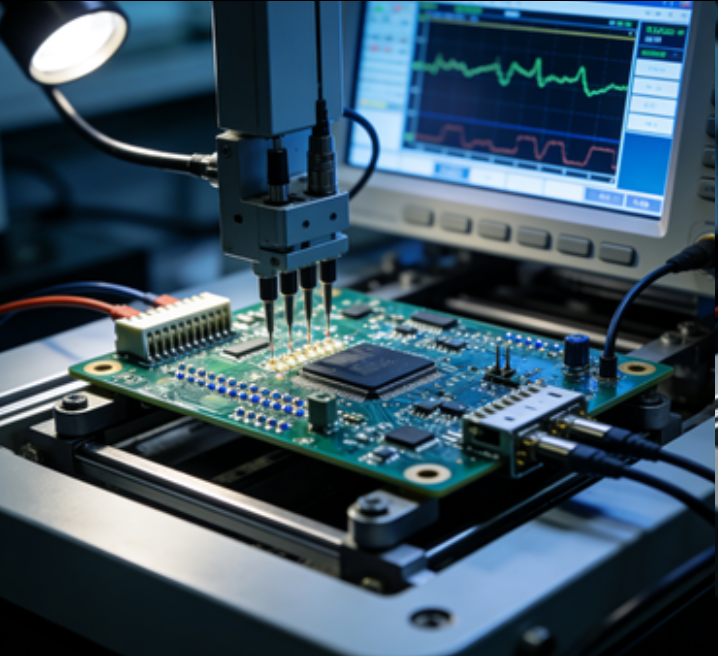

PCBA (Printed Circuit Board Assembly) electrical performance testing ensures that assembled boards meet functional specifications by verifying signal integrity, power distribution, and component behavior. Key tests include in-circuit testing (ICT), flying probe testing, and functional testing. ICT uses bed-of-nails fixtures to measure resistance, capacitance, and diode polarity at predefined test points, achieving 99% fault coverage for open/short circuits. Flying probe testing, ideal for prototypes, employs movable probes to test high-density boards without custom fixtures, reducing setup costs by 40% compared to ICT. Functional testing validates end-to-end system behavior, such as USB 3.2 data rates (10Gbps) in laptops or power efficiency in EV battery management systems (BMS).

Advanced techniques like boundary scan (JTAG) test embedded components in BGA packages, where physical access is limited. For high-speed signals (e.g., 56Gbps PCIe 5.0), differential pair impedance testing ensures traces meet ±10% tolerance, preventing signal degradation. Power integrity analysis uses oscilloscopes to measure voltage ripple (<50mVpp for DC-DC converters) and transient response (recovery time <10μs). Automated test equipment (ATE) integrates these methods, reducing testing time by 60% in automotive ECUs.

Challenges include handling mixed-signal boards (analog/digital coexistence) and testing under thermal stress (-40°C to 125°C for aerospace applications). Solutions involve thermal chambers paired with real-time monitoring. Future trends include AI-driven anomaly detection in oscilloscope data and cloud-based test result analytics for global manufacturing.