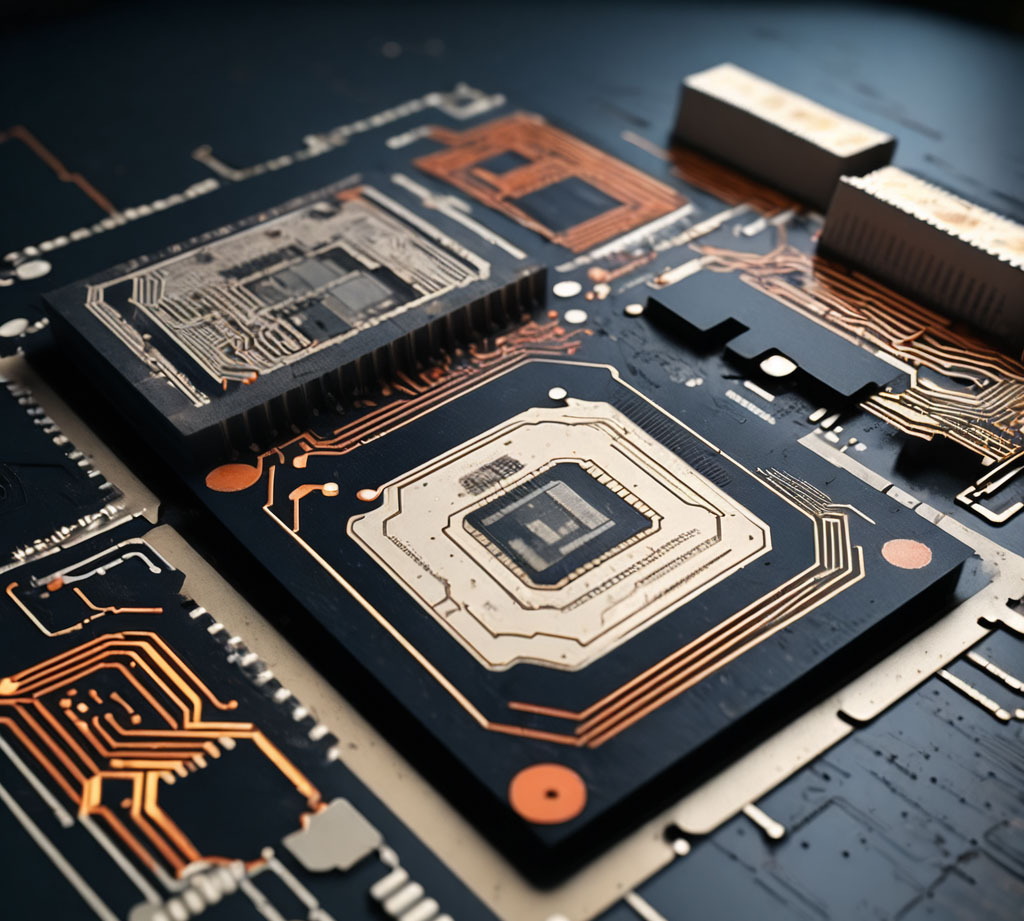

New energy PCBA

As the global energy transition accelerates, the field of new energy is thriving. New energy electronic products, as an integral part of this transition, are experiencing a growing demand for Printed Circuit Board Assembly (PCBA). In order to meet the PCBA requirements of clients in the new energy sector, we are introducing the New Energy PCBA Customization Service.

Service Offerings:

Needs Analysis: In-depth communication with clients to understand their PCBA requirements for new energy products, including circuit board dimensions, types of components, and performance specifications.

Circuit Board Design: Customized design of circuit boards based on client requirements, ensuring a rational layout, stable performance, and compliance with the specific needs of new energy products.

Component Selection and Procurement: Providing clients with high-quality component selection and procurement services, ensuring that the chosen components meet the performance and reliability requirements of new energy products.

PCB Manufacturing and Soldering: Utilizing advanced PCB manufacturing technology and soldering processes to ensure the precision and quality of circuit boards, while improving production efficiency.

Circuit Board Testing and Debugging: Rigorous testing and debugging of the customized PCBA to ensure that performance metrics meet expectations, accompanied by the provision of comprehensive testing reports for clients.

Delivery and After-Sales Support: Timely delivery of the completed custom PCBA according to agreed-upon timelines and quantities. Continuous provision of after-sales technical support to address any issues clients may encounter during usage.

Project Advantages:

Professional Team: We have an experienced team of new energy PCBA designers capable of providing professional technical support and solutions.

High-Quality Components: Collaborating with renowned component suppliers to ensure the high quality and reliability of selected components.

Strict Quality Control: Employing a stringent quality control system to ensure precision and quality at every stage of production, delivering high-quality PCBA products to clients.

Quick Response: Prioritizing project timeliness and responsiveness to ensure the swift satisfaction of clients' urgent needs.

After-Sales Assurance: Providing comprehensive after-sales service to address any issues clients may encounter during product usage, ensuring client satisfaction.