-

CN

-

Service Hotline

+8618129931046 Mr. Liao

PCB polyester film, also known as polyethylene terephthalate (PET) film, is a versatile material widely used in printed circuit board manufacturing due to its unique combination of properties. This thin, flexible, and durable film offers excellent electrical insulation, chemical resistance, and mech

Sep 11, 2025

Sep 11, 2025

1

1

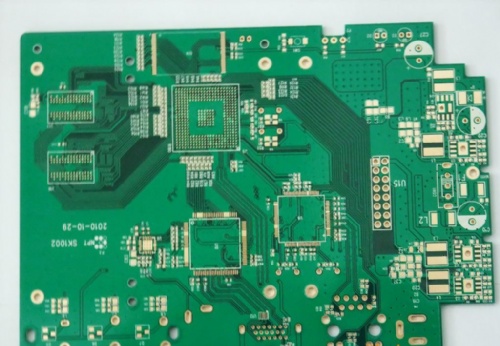

PCB high TG (Glass Transition Temperature) materials have emerged as a crucial component in modern printed circuit board manufacturing, especially in applications demanding high - performance and reliability. The glass transition temperature represents the point at which a material transitions from

Sep 10, 2025

Sep 10, 2025

1

1

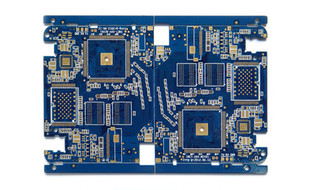

HDI PCBs, or High - Density Interconnect Printed Circuit Boards, have emerged as a revolutionary solution in the electronics manufacturing industry, enabling the creation of compact, high - performance electronic devices. HDI PCBs are characterized by their significantly higher component density and

Sep 09, 2025

Sep 09, 2025

1

1

PCB screen printing inks are essential materials in the printed circuit board (PCB) manufacturing process, playing a crucial role in the production of high - quality, functional PCBs. These inks are specifically formulated to meet the unique requirements of PCB fabrication, including providing clear

Sep 08, 2025

Sep 08, 2025

1

1

The PCB surface copper cladding layer is a fundamental and indispensable part of printed circuit boards, playing a crucial role in establishing electrical connections and enabling the proper functioning of electronic circuits. This layer is typically made of high - purity copper, which is carefully

Sep 05, 2025

Sep 05, 2025

1

1

PCB surface mount resistors are indispensable passive electronic components widely utilized in printed circuit boards (PCBs) for their role in controlling the flow of electric current, dividing voltages, and providing impedance matching. These resistors are designed to be mounted directly onto the s

Sep 04, 2025

Sep 04, 2025

1

1