-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-09-10 Views:1

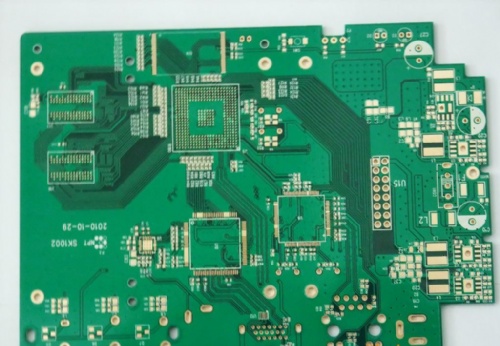

PCB high TG (Glass Transition Temperature) materials have emerged as a crucial component in modern printed circuit board manufacturing, especially in applications demanding high - performance and reliability. The glass transition temperature represents the point at which a material transitions from a rigid, glassy state to a more rubbery, flexible state. High TG materials, typically with a TG value above 170°C, offer enhanced thermal stability, making them ideal for advanced electronic devices exposed to elevated temperatures during operation, soldering, or in high - temperature environments.

The primary advantage of high TG PCB materials lies in their superior thermal performance. In processes like surface mount technology (SMT) reflow soldering, where temperatures can exceed 250°C for short durations, high TG materials maintain their structural integrity and dimensional stability. This prevents issues such as warping, delamination, and solder joint failures, which can occur with lower TG materials. The enhanced thermal resistance also enables better heat dissipation, reducing the risk of thermal stress on components and improving the overall lifespan of the PCB. For instance, in automotive electronics, where PCBs are subjected to the heat generated by engines and other components, high TG materials ensure reliable operation over extended periods.

High TG PCB materials are often composed of advanced resin systems, such as modified epoxy resins. These resins are formulated with specific additives and fillers to achieve the desired high TG value while maintaining good electrical insulation properties and mechanical strength. Reinforcement materials, like woven glass fibers, are integrated into the resin matrix to enhance the material's mechanical rigidity and resistance to mechanical stresses. The combination of these components results in a material that can withstand repeated thermal cycling and mechanical vibrations, which are common in many electronic applications, including aerospace and industrial control systems.

In terms of manufacturing, high TG PCB materials require specialized processes and equipment. The higher curing temperatures and longer processing times associated with these materials demand precise control to ensure proper resin cross - linking and full - cure. This can increase the manufacturing complexity and cost compared to lower TG materials. However, the benefits in terms of improved performance and reliability often outweigh these additional costs, especially for high - end applications. Quality control during the manufacturing of high TG PCBs is also crucial, as any defects in the material or the manufacturing process can lead to significant failures in the final product. Tests such as thermal shock testing, where the PCB is subjected to rapid temperature changes, are commonly performed to verify the material's performance and durability. Overall, high TG PCB materials play a vital role in enabling the development of advanced, reliable electronic products in a wide range of industries.