-

CN

-

Service Hotline

+8618129931046 Mr. Liao

A PCB dust cover is a protective enclosure designed to shield printed circuit boards from dust, debris, moisture, and other environmental contaminants that can degrade performance or cause electrical failures. These covers are essential in applications such as industrial machinery, outdoor electroni

Jan 30, 2026

Jan 30, 2026

1

1

PCB thermal design focuses on managing heat generation and dissipation within a printed circuit board to ensure components operate within their safe temperature ranges, preventing performance degradation, reliability issues, or premature failure. Electronic components—especially high-power devices l

Jan 29, 2026

Jan 29, 2026

1

1

The environmental adaptability of flex-rigid PCBs refers to their ability to maintain structural integrity and electrical performance across a wide range of harsh operating conditions—including extreme temperatures, humidity, vibration, mechanical stress, and chemical exposure. Unlike traditional ri

Jan 27, 2026

Jan 27, 2026

1

1

Customizable flexible PCB circuit boards offer unparalleled design flexibility and have revolutionized the electronics industry by enabling the creation of innovative and compact electronic devices. Unlike rigid PCBs, flexible PCBs are made from flexible substrate materials, such as polyimide or pol

Jan 24, 2026

Jan 24, 2026

1

1

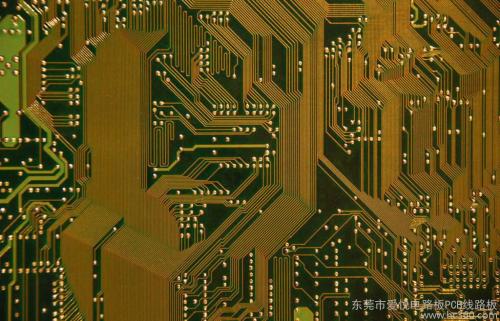

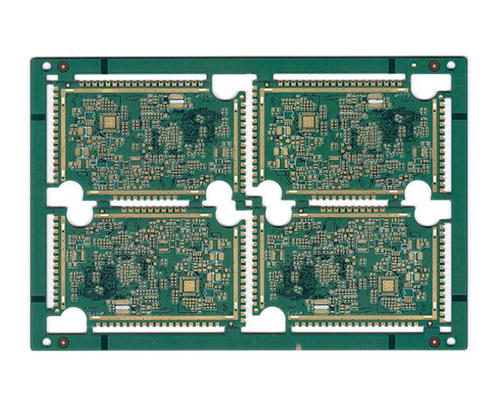

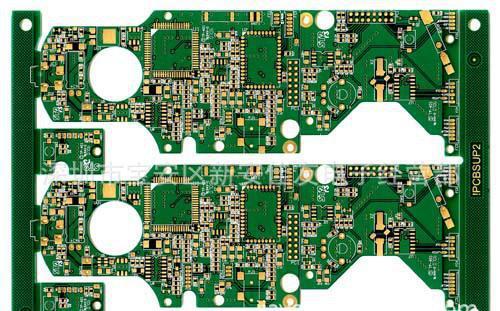

Multilayer high - density PCB (Printed Circuit Board) circuit boards represent the pinnacle of PCB technology, designed to meet the growing demand for compact, high - performance, and complex electronic systems. These boards are characterized by their multiple layers of conductive traces, insulating

Jan 23, 2026

Jan 23, 2026

1

1

PCB LED beads have become a cornerstone in modern electronic devices, offering a versatile and efficient lighting solution with a wide range of applications. These light - emitting diodes (LEDs) are specifically designed for integration onto printed circuit boards, providing designers with the flexi

Jan 22, 2026

Jan 22, 2026

1

1