-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-08-29 Views:1

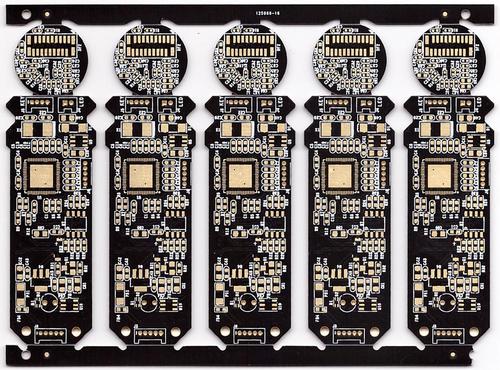

The Waterproof PCB is a specialized printed circuit board engineered to prevent water, moisture, and liquid ingress, ensuring stable electrical performance in wet or submerged environments—such as marine electronics, outdoor IoT sensors, waterproof consumer devices (e.g., action cameras), and industrial equipment exposed to washdowns. Unlike standard PCBs (which fail quickly when wet due to short circuits or corrosion), waterproof PCBs use advanced materials and protective coatings to meet IP (Ingress Protection) ratings like IP67 or IP68, making them suitable for temporary or long-term water exposure.

Core to its waterproof design is the use of conformal coatings. These thin, protective layers (10-50 μm thick) are applied to the PCB’s surface, covering components and traces to block water. Common coatings include silicone (flexible, heat-resistant up to 200°C), polyurethane (chemical-resistant, ideal for industrial use), and PTFE (fluoropolymer, highly water-repellent for marine applications). The coating is applied via spray, dip, or selective deposition, ensuring full coverage of critical areas like solder joints and component leads. For enhanced protection, some designs use encapsulation—pouring a rigid epoxy resin over the entire PCB to form a waterproof barrier, though this limits component accessibility for repairs.

Material selection also plays a key role. The PCB substrate (base material) uses water-resistant FR-4 variants (e.g., high-Tg FR-4 with a glass transition temperature >170°C) or specialty materials like PTFE (for high-frequency applications), which resist water absorption. Conductive traces are made from thick copper (70-105 μm) plated with nickel-gold (ENIG) or tin-silver, which prevent corrosion if water seeps through the coating. Solder masks (the green/blue layer on PCBs) are made from water-resistant epoxy or acrylic, with no pinholes—tested via bubble tests to ensure no moisture penetration.

Testing validates waterproof performance. Manufacturers subject the PCB to IEC 60529 tests: IP67 involves submersion in 1m of water for 30 minutes, while IP68 requires submersion in deeper water (e.g., 10m) for 24 hours. After testing, the PCB is checked for electrical continuity, insulation resistance (must remain >100 MΩ at 500V DC), and no component damage. Environmental cycling (temperature -40°C to 85°C + humidity 85%) is also performed to ensure the coating/encapsulation does not crack over time.

Whether powering a marine GPS or an outdoor weather sensor, the Waterproof PCB delivers reliable performance—protecting electronics from water damage in harsh, wet environments.