-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-07-18 Views:1

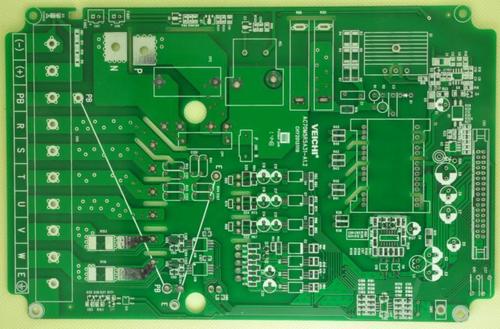

Moisture can severely degrade the performance and lifespan of single - sided printed circuit boards (PCBs), leading to issues such as corrosion of metal traces, electrical short - circuits, and component failure. Therefore, effective moisture - proof treatment methods are essential to ensure the reliability of single - sided PCBs, especially in humid or high - moisture environments.

One of the most common moisture - proof treatment methods is the application of a conformal coating. Conformal coatings are thin, protective films that are applied over the surface of the PCB to create a barrier against moisture, dust, and other contaminants. There are several types of conformal coatings available, including acrylics, polyurethanes, and epoxies. Acrylic conformal coatings offer good moisture resistance and are relatively easy to apply, making them a popular choice for general - purpose applications. Polyurethane coatings, on the other hand, provide excellent abrasion resistance in addition to moisture protection, which is beneficial for PCBs that may be subject to physical wear. Epoxy conformal coatings offer the highest level of chemical and moisture resistance, making them suitable for harsh industrial environments. The application process of conformal coatings typically involves spraying, brushing, or dipping the PCB into the coating material, followed by a curing process that can be achieved through heat, UV light, or air drying.

Another approach to moisture - proofing single - sided PCBs is the use of moisture - resistant materials during the PCB manufacturing process. For example, choosing a laminate material with low water absorption properties can significantly reduce the amount of moisture that penetrates the PCB substrate. FR - 4, a commonly used fiberglass - epoxy laminate, has relatively good moisture resistance, but there are also specialized high - performance laminates available that offer even better protection. Additionally, using moisture - resistant soldermask materials can further enhance the PCB's ability to withstand moisture. These soldermask materials form a protective layer over the copper traces, preventing direct contact with moisture and reducing the risk of corrosion.

In some cases, encapsulation or potting can be used as a more comprehensive moisture - proof treatment. Encapsulation involves covering the entire PCB with a protective material, such as a thermosetting resin, which completely seals the board from the external environment. Potting is similar but typically involves filling the voids and cavities on the PCB with a potting compound, providing both mechanical protection and moisture resistance. While encapsulation and potting offer excellent moisture protection, they can also make component replacement and board repair more difficult, so they are usually reserved for applications where high - level protection is required, such as in outdoor or underwater electronic devices.