-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-07-01 Views:1

Thermal simulation analysis of multi - layer circuit boards is vital for predicting and managing heat dissipation, ensuring that the components on the board operate within their safe temperature ranges and preventing performance degradation or component failure due to overheating.

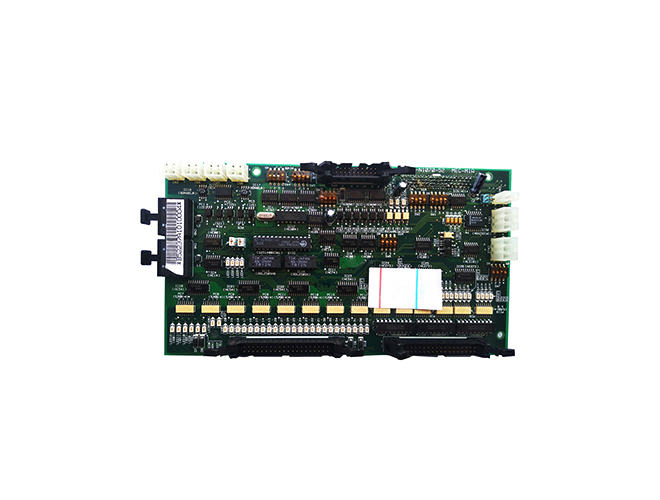

The first step in thermal simulation analysis is to create an accurate model of the multi - layer circuit board. This model includes detailed representations of all components, such as integrated circuits, resistors, capacitors, and heat - sinks (if present), as well as the PCB layers themselves. The physical dimensions, material properties (including thermal conductivity, specific heat, and density), and power - dissipation characteristics of each component are carefully defined. For example, the thermal conductivity of the PCB substrate material, which can vary depending on the type of laminate used (e.g., FR - 4, Rogers), significantly affects the heat - transfer efficiency within the board. Advanced computer - aided design (CAD) and electronic design automation (EDA) tools are employed to build these models, often integrating data from component datasheets and PCB layout files.

Once the model is created, various thermal - analysis methods can be applied. One commonly used method is computational fluid dynamics (CFD). CFD simulations consider the effects of air flow around the PCB, which is crucial for forced - convection cooling scenarios, such as when fans or blowers are used to cool the board. By solving the equations of fluid motion and heat transfer, CFD can predict the temperature distribution on the PCB surface and within the components, taking into account factors like air velocity, temperature, and turbulence. Another approach is finite - element analysis (FEA), which focuses on the conduction of heat through the solid materials of the PCB and components. FEA divides the model into a mesh of small elements and calculates the heat flow and temperature changes within each element based on the applied power loads and material properties. This method is particularly effective for analyzing the thermal behavior of complex geometries and for understanding the heat - transfer paths within the PCB layers.

Thermal simulation analysis also involves setting appropriate boundary conditions. These conditions define the environment in which the PCB operates, such as the ambient temperature, air - flow rate (if applicable), and the thermal resistance of heat - sinks or other cooling devices. For example, in an automotive application, the ambient temperature may range from - 40°C to 85°C, and the thermal simulation model needs to account for these extreme temperature conditions. Additionally, the simulation can be used to optimize the PCB layout for better heat dissipation. By analyzing the temperature distribution results, designers can identify hotspots on the board and make adjustments, such as increasing the size of copper traces for power delivery to reduce resistive heating, or repositioning components to improve natural or forced - convection cooling. Overall, thermal simulation analysis is an indispensable tool in the design process of multi - layer circuit boards, enabling designers to proactively address thermal - management challenges and ensure the long - term reliability of electronic systems.