-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-11-27 Views:1

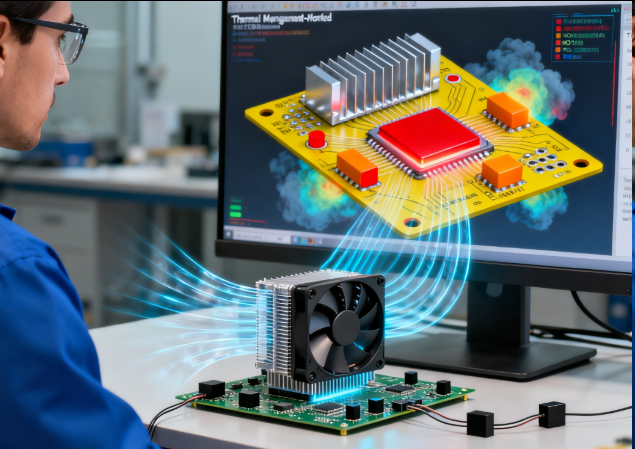

Thermal Management-Oriented PCBA Design is a design approach that optimizes printed circuit board assemblies to dissipate heat efficiently, preventing component overheating, which can cause performance degradation, shortened lifespan, or catastrophic failure. Unlike designs that ignore thermal effects, thermal management design identifies heat sources (e.g., high-power ICs, LEDs) and implements strategies to transfer heat away from critical components—critical for applications like power electronics, automotive, industrial control systems, and high-performance computing (HPC) where components generate significant heat.

The core of thermal management PCBA design lies in heat dissipation and temperature control. Key technical strategies include: 1) Component Placement for Heat Distribution: Placing high-power components (e.g., voltage regulators, power transistors, LEDs) in low-temperature areas of the PCB—away from heat-sensitive components (e.g., microcontrollers, sensors, batteries) and near board edges or heat sinks (where heat can escape easily). Spacing high-power components evenly across the PCB to avoid “hot spots” (areas with localized high temperatures). For example, placing two 5W voltage regulators on opposite sides of the PCB instead of adjacent to each other reduces their mutual heating by 15-20%. 2) Thermal Vias and Copper Pours: Using thermal vias (copper-plated holes) to transfer heat from the top layer of the PCB to inner layers or the bottom layer, where it can be dissipated more effectively. Thermal vias are placed in clusters under high-power components (e.g., 4-8 vias under a voltage regulator) and filled with solder or copper to maximize heat transfer. Adding copper pours (large areas of solid copper) connected to ground or power planes—copper is an excellent heat conductor, so pours spread heat across the PCB, reducing hot spot temperatures. For example, a 1oz copper pour under a 10W LED can reduce its temperature by 25-30°C. 3) Heat Sinks and Thermal Interface Materials (TIMs): Integrating heat sinks with high-power components—attaching passive heat sinks (aluminum or copper) directly to component packages using TIMs (e.g., thermal grease, thermal pads) to fill air gaps and improve heat transfer. For very high-power components (e.g., 20W+), using active cooling (e.g., small fans or heat pipes) to enhance heat dissipation. Ensuring heat sinks are compatible with the PCB’s mechanical design—avoiding interference with other components or the device enclosure. 4) PCB Material and Copper Thickness: Selecting PCB materials with high thermal conductivity—using metal-core PCBs (MCPCBs, with a aluminum or copper core) instead of standard FR-4 for high-power applications like LED lighting. MCPCBs have thermal conductivity 5-10x higher than FR-4, enabling faster heat dissipation. Increasing copper thickness (e.g., 2oz instead of 1oz) for power traces—thicker copper conducts heat better and reduces resistive heating (I²R loss) in high-current traces.

Thermal management design requires thermal simulation early in the design process. Engineers use thermal analysis tools (e.g., ANSYS Icepak, Mentor Graphics FloTHERM) to model heat generation and dissipation, predicting component temperatures and identifying hot spots. Physical testing with thermal cameras (to visualize temperature distribution) and thermocouples (to measure component temperatures) validates the design—ensuring all components operate within their specified temperature ranges (e.g., -40°C to 85°C for industrial components).

Application scenarios demonstrate thermal management’s impact. In power electronics (e.g., electric vehicle (EV) inverters), thermal management PCBs use MCPCBs, thermal vias, and heat pipes to dissipate heat from 100W+ power transistors, ensuring reliable operation in the vehicle’s engine bay. In HPC servers, thermal design uses copper pours, heat sinks, and active cooling to keep CPUs and GPUs below 85°C, maintaining peak performance. In industrial control systems (e.g., motor drives), thermal vias and evenly spaced power components prevent overheating in factory environments with temperatures up to 60°C. In LED lighting, MCPCBs with copper pours reduce LED junction temperatures by 30-40°C, extending LED lifespan from 50,000 to 100,000 hours. With overheating being a leading cause of PCBA failure, thermal management design is essential for delivering reliable, long-lasting products.