-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-07-22 Views:1

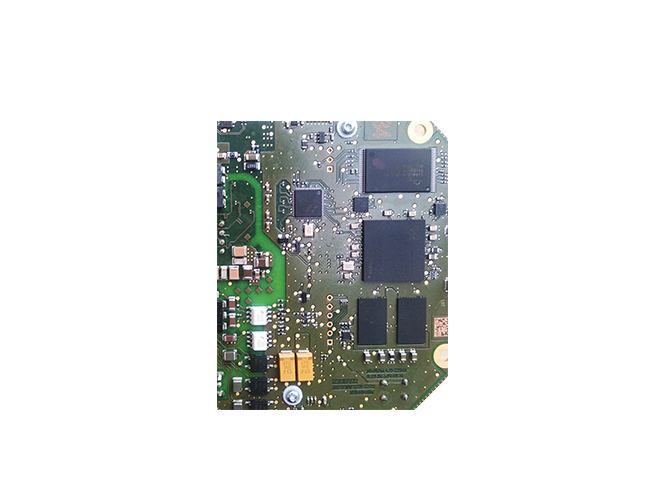

Rigid printed circuit boards (PCBs) are foundational components in electronic devices, and their standardized design ensures compatibility, reliability, and manufacturability across industries. These specifications, established by organizations like IPC (Association Connecting Electronics Industries) and IEEE, cover dimensions, materials, layer configurations, and performance criteria to streamline production and ensure consistent quality.

Material standards are critical for rigidity and performance. Rigid PCBs typically use FR-4 (flame-retardant glass-reinforced epoxy) as the base material, specified by IPC-4101, which defines mechanical properties like tensile strength (≥200 MPa) and thermal resistance (Tg ≥130°C for standard applications). For high-temperature environments (e.g., automotive or industrial), materials like FR-5 or polyimide-based substrates (Tg ≥170°C) are used, adhering to stricter standards for heat tolerance. Copper foil thickness, specified by IPC-4562, ranges from 0.5 oz (17.5 μm) for low-current circuits to 3 oz (105 μm) for power applications, ensuring proper current carrying capacity.

Dimensional and layer specifications ensure compatibility with manufacturing processes. IPC-2221 outlines general design standards, including minimum trace widths (≥0.1 mm for 1 oz copper) and spacing (≥0.1 mm) to prevent short circuits. Hole sizes, both through-hole and blind/buried vias, follow IPC-2226, with minimum diameters of 0.2 mm for vias to accommodate component leads. Layer counts are standardized based on application: consumer electronics often use 2-4 layers, while industrial systems may require 6-12 layers, with each layer’s thickness (typically 0.1-0.2 mm) controlled to maintain overall board rigidity.

Design for Manufacturability (DFM) standards reduce production errors. Specifications include minimum board size (50x50 mm for automated assembly) and maximum aspect ratio (board length/width ≤5:1) to prevent warping during fabrication. Solder mask and silkscreen standards (IPC-SM-840 and IPC-2221) define coating thickness (20-50 μm) and ink durability, ensuring clear component labeling and protection against environmental damage.

Electrical performance standards address signal integrity. IPC-2141 specifies characteristic impedance (50Ω ±10% for high-speed signals) and dielectric constant (εr ≈4.5 for FR-4) to minimize signal loss. For power circuits, current carrying capacity calculations (per IPC-2221) ensure traces can handle expected currents without overheating, with derating factors for ambient temperatures above 25°C.

Adhering to these standards ensures rigid PCBs meet performance requirements, reduce production costs, and facilitate interoperability across global supply chains, making them reliable for applications from consumer electronics to industrial machinery.