-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-10-28 Views:1

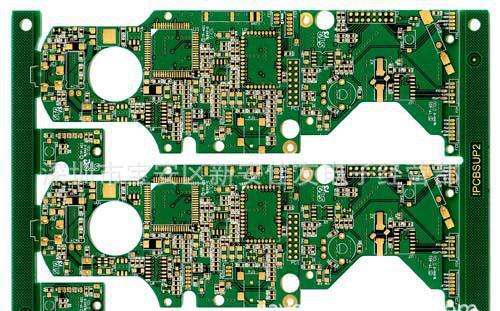

A specialized PCB for ventilators is a critical component that plays a pivotal role in ensuring the proper functioning and safety of these life - saving medical devices. Ventilators are essential in clinical settings, especially in intensive care units, to assist patients with breathing difficulties by delivering oxygen - rich air or removing carbon dioxide from the lungs. The PCB for ventilators must be meticulously designed and manufactured to meet the stringent requirements of the medical industry, combining high - precision electronics with robust reliability.

The design of a ventilator - specific PCB begins with a deep understanding of the device's complex functions. It needs to control multiple aspects, such as the regulation of air pressure, flow rate, and oxygen concentration. To achieve this, the PCB integrates a variety of components, including microcontrollers, sensors, and actuators. Microcontrollers act as the "brain" of the system, processing signals from various sensors and sending commands to the actuators to adjust the ventilator's operation. Pressure sensors are crucial for measuring the air pressure within the ventilator circuit, ensuring that the pressure delivered to the patient is within the safe and therapeutic range. Oxygen sensors, on the other hand, monitor the oxygen concentration in the gas mixture to provide accurate and appropriate oxygen supply.

Electrical isolation and safety features are of utmost importance in ventilator PCBs. Given that these devices are directly connected to patients, any electrical malfunction could pose a serious risk. Therefore, the PCB is designed with comprehensive electrical isolation techniques to prevent electrical leakage and short circuits. High - quality insulation materials are used to separate different electrical circuits, and strict grounding and shielding measures are implemented to protect against electromagnetic interference (EMI). In addition, the PCB is equipped with fail - safe mechanisms. For example, if a critical component fails or an abnormal condition is detected, the PCB can trigger an alarm system and automatically adjust or stop the ventilator's operation to safeguard the patient's safety.

The manufacturing process of ventilator PCBs adheres to strict quality control standards. Advanced surface - mount technology (SMT) is often employed to precisely place and solder components onto the PCB. Each component is carefully inspected during and after the assembly process to ensure its proper functioning and correct placement. The PCB undergoes rigorous testing, including electrical testing, functional testing, and environmental testing. Electrical testing checks for continuity, insulation resistance, and proper voltage and current flow. Functional testing simulates the actual operation of the ventilator to verify that all functions are working correctly. Environmental testing subjects the PCB to various conditions, such as temperature, humidity, and vibration, to ensure its reliability in different clinical environments. A well - designed and manufactured specialized PCB for ventilators is essential for the effective and safe operation of these vital medical devices, ultimately contributing to the well - being and recovery of patients.