-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-12-01 Views:1

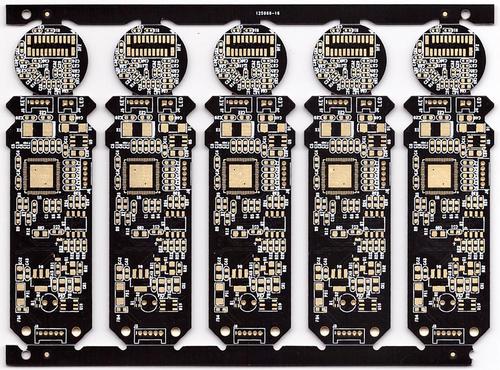

Smart Wearable PCBA refers to specialized Printed Circuit Board Assemblies designed for integration into wearable devices—such as smartwatches, fitness trackers, smart bands, and health monitors—that combine compact size, low power consumption, and multi-sensor integration to deliver real-time data tracking and user-centric functions. Unlike general consumer electronics PCBA, smart wearable PCBA must prioritize miniaturization (to fit into small, lightweight devices), ultra-low power (to extend battery life for all-day use), and durability (to withstand daily wear, sweat, and occasional impacts)—making it a core component in the fast-growing wearable technology industry.

The core technical characteristics of Smart Wearable PCBA include miniaturized component selection and optimized circuit design. To achieve compactness, PCBs use ultra-small form factors (often 2–5 cm in size) with high-density interconnects (HDI) and surface-mount technology (SMT) components like 01005 resistors (0.4mm × 0.2mm) and tiny microcontrollers (MCUs) from brands like STMicroelectronics or Nordic Semiconductor. These MCUs are chosen for their low power consumption (operating at 1–3.3V with microamp-level idle current) to support long battery life—critical for devices that rely on small lithium-ion batteries (300–500 mAh). The PCBA also integrates a range of sensors tailored to wearable use cases: biometric sensors (heart rate monitors, blood oxygen sensors like Maxim Integrated’s MAX30102), motion sensors (accelerometers, gyroscopes from Bosch or InvenSense), and environmental sensors (temperature, UV light sensors) to collect user data.

Design considerations for Smart Wearable PCBA focus on power management, durability, and user comfort. Power management circuits include low-dropout regulators (LDOs) and power-saving modes (e.g., deep sleep mode for MCUs when not actively sensing) to minimize energy use. Durability is ensured by using moisture-resistant coatings (e.g., conformal coatings like Parylene) to protect components from sweat and humidity, and flexible PCBs (FPCBs) for devices like smart bands that need to bend with the user’s wrist. Additionally, thermal management is critical—components are arranged to avoid heat buildup near the skin, preventing user discomfort.

Practical applications of Smart Wearable PCBA span consumer health and fitness. In smartwatches, the PCBA powers features like real-time heart rate monitoring, GPS tracking for workouts, and notifications from paired smartphones. In fitness trackers, it counts steps, monitors sleep patterns, and calculates calorie burn using motion sensor data. In specialized wearables (e.g., medical-grade fitness bands), it may include FDA-approved sensors for blood pressure monitoring or ECG (electrocardiogram) functionality. While Smart Wearable PCBA faces challenges like balancing miniaturization with heat dissipation and sensor accuracy, its role in enabling portable, user-friendly health and fitness technology makes it indispensable. For any wearable device manufacturer, a well-designed Smart Wearable PCBA is key to delivering reliable, long-lasting products that meet consumer expectations.