-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-07-17 Views:1

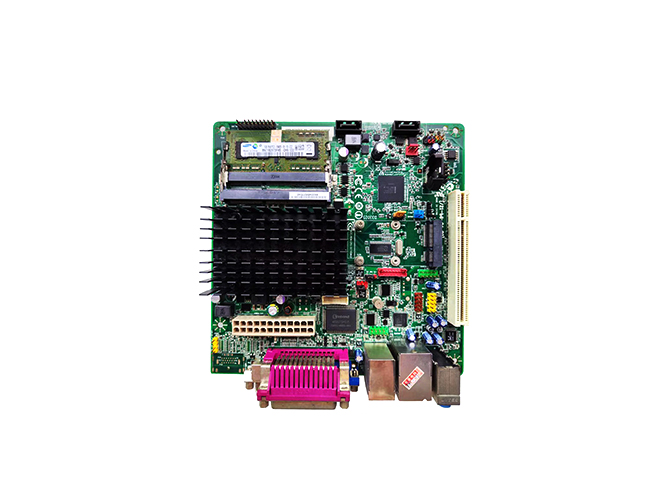

Rigid printed boards (PCBs) play a pivotal role in power equipment control circuits, providing a stable and reliable platform for integrating complex electronic components that regulate, monitor, and protect power systems. Their mechanical robustness and electrical performance make them indispensable in applications such as motor drives, inverters, transformers, and power distribution units.

One key application is motor control systems, where rigid PCBs host microcontrollers, gate drivers, and sensor interfaces. These boards manage motor speed, torque, and direction by processing feedback from current, voltage, and position sensors (e.g., encoders). The rigid structure ensures that components remain securely mounted under the mechanical stress of industrial environments, while the PCB’s trace routing—optimized for low impedance—minimizes voltage drops in high-current paths, critical for efficient motor operation.

In power inverters and converters, rigid PCBs integrate switching devices (IGBTs, MOSFETs) and control logic, converting DC power to AC (or vice versa) with high efficiency. The boards’ thermal management capabilities, enhanced by copper pours and heat sinks attached to high-power components, dissipate heat generated during switching, preventing overheating and ensuring long-term reliability. Rigid PCBs also support isolation techniques (e.g., optocouplers, transformers) to separate high-voltage power stages from low-voltage control circuits, enhancing safety and reducing noise.

Protection circuits on rigid PCBs safeguard power equipment from faults such as overcurrent, overvoltage, and short circuits. Components like fuses, transient voltage suppressors (TVS), and relay drivers are mounted on the board, enabling rapid response to abnormal conditions. The rigid PCB’s stable layout ensures that protection signals propagate without delay, minimizing damage to expensive equipment.

Moreover, rigid PCBs facilitate communication and monitoring in smart power systems. They integrate communication interfaces (e.g., RS-485, Ethernet, Wi-Fi) that enable remote monitoring of power parameters, allowing for predictive maintenance and real-time adjustments. Their compatibility with surface-mount technology (SMT) and through-hole components supports dense integration, reducing the size of control units while increasing functionality.

rigid PCBs provide the mechanical stability, thermal performance, and electrical integrity required for power equipment control circuits, ensuring safe, efficient, and reliable operation in demanding industrial environments.