-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-11-08 Views:1

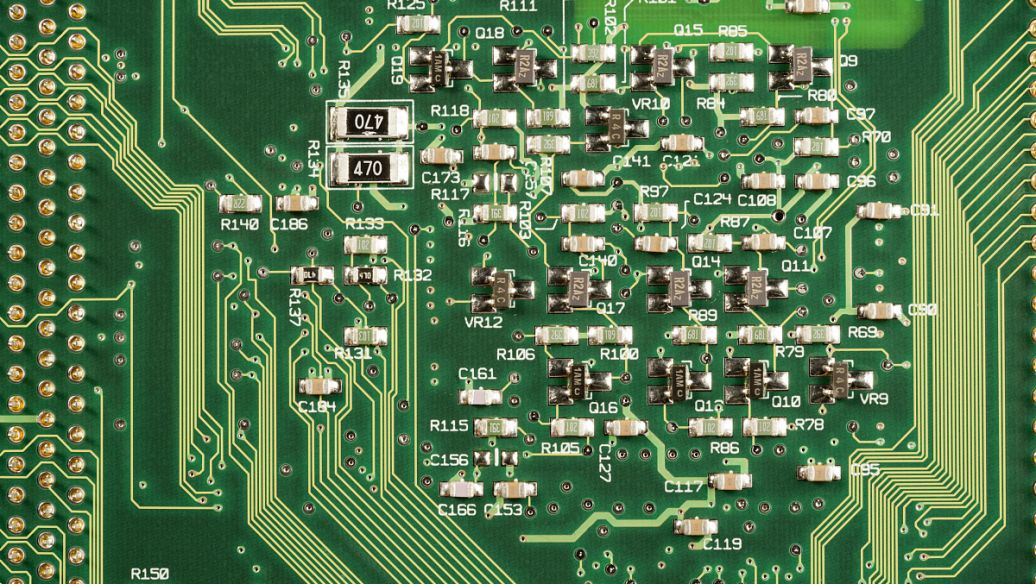

PCB vibration testing evaluates a PCB’s mechanical durability and reliability under cyclic or random vibration conditions—simulating the real-world environments the PCB will encounter during transportation (e.g., truck shipping, air cargo) or operation (e.g., automotive engines, industrial machinery). Unlike static mechanical tests (which assess strength under constant force), vibration testing focuses on how repeated motion affects the PCB’s structure (e.g., trace integrity, component soldering) and electrical performance, identifying potential failures like loose components, cracked traces, or broken solder joints before the product reaches end-users. This test is mandatory for PCBs in high-vibration industries such as automotive, aerospace, and industrial automation.

The PCB vibration testing process follows four key steps: 1) Test Standard Selection: Choose industry-specific standards to define test parameters—common standards include: - IEC 60068-2-6: Specifies sinusoidal vibration (cyclic motion at fixed frequencies) for general electronics. - IEC 60068-2-27: Covers random vibration (variable frequencies, simulating real-world chaos) for automotive and aerospace PCBs. - ISO 16750-3: Automotive-specific standard defining vibration levels for different vehicle zones (e.g., engine bay vs. passenger compartment). For example, an engine bay PCB would undergo random vibration with 10g acceleration (5-2000Hz), while a dashboard PCB might use 5g acceleration. 2) Test Setup: Mount the PCB securely to a vibration shaker (a device that generates controlled vibration) using fixtures that replicate the PCB’s actual installation (e.g., screws, clips). Connect the PCB to a data acquisition system (DAS) via test probes to monitor electrical parameters (e.g., resistance, voltage, signal integrity) in real time. For multi-component PCBs, attach accelerometers to critical components (e.g., BGA chips, connectors) to measure vibration transmission. 3) Test Execution: Run the vibration sequence based on the selected standard: - Sinusoidal Vibration: Sweep frequencies from low to high (e.g., 10Hz to 2000Hz) at fixed acceleration levels, holding each frequency for a set duration (e.g., 1 minute per frequency). This identifies “resonance points” where the PCB vibrates most intensely—common failure spots. - Random Vibration: Apply a frequency spectrum with varying acceleration (e.g., 5-2000Hz, 5g RMS) for an extended period (e.g., 24 hours), simulating weeks of transportation or operation. Monitor the DAS for sudden changes (e.g., a spike in resistance indicating a cracked trace). 4) Post-Test Evaluation: Inspect the PCB visually (using a microscope) for physical damage (e.g., cracked traces, lifted pads, loose components) and retest its electrical performance (e.g., functional testing, continuity testing). A common failure found in automotive PCBs is cracked solder joints on power connectors, which only appear after hours of random vibration.

An automotive supplier reported that vibration testing reduced field failures of engine control unit (ECU) PCBs by 55%—catching cracked traces that would have failed after 6 months of vehicle operation. For PCBs in critical applications (e.g., aircraft avionics), vibration testing is paired with environmental testing (e.g., temperature cycling) to simulate combined stressors, ensuring maximum reliability.