-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-09-17 Views:1

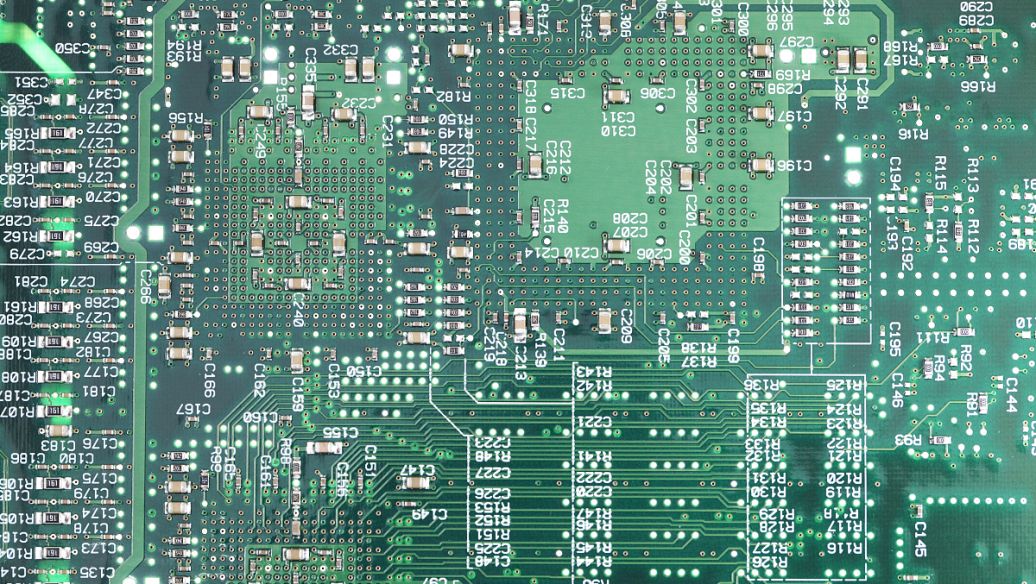

Printed Circuit Board (PCB) thermal testing is a crucial process in the design and manufacturing of PCBs, aimed at evaluating how the board behaves under different thermal conditions. As electronic devices become more compact and powerful, the heat generated by components mounted on PCBs has increased significantly. Poor thermal management can lead to reduced component performance, premature failure, and even system - level malfunctions. Therefore, thermal testing helps ensure that PCBs can operate reliably within their specified temperature ranges.

There are several methods employed in PCB thermal testing. One common approach is the use of thermal imaging cameras. These cameras capture infrared radiation emitted by the PCB and its components, allowing engineers to visualize the temperature distribution across the board. By analyzing the thermal images, hotspots can be easily identified. Hotspots are areas on the PCB where the temperature is significantly higher than the surrounding areas, often due to components with high power consumption or poor heat dissipation paths. For example, in a high - performance graphics card PCB, the GPU and power - delivery components may generate a large amount of heat, and thermal imaging can help determine if the heat sinks and cooling mechanisms are effectively dissipating this heat.

Another important thermal testing method is the use of temperature sensors. These sensors, such as thermocouples or resistance temperature detectors (RTDs), are placed at critical locations on the PCB, including near high - power components and in areas with complex heat - flow patterns. The sensors continuously monitor the temperature during testing and provide accurate temperature readings over time. This data can be used to create thermal profiles of the PCB, which are essential for understanding the thermal behavior of the board under various operating conditions, such as continuous high - load operation or rapid temperature changes.

In addition to steady - state thermal testing, transient thermal testing is also conducted. Transient thermal testing simulates sudden changes in power input or environmental temperature, mimicking real - world scenarios like when a device is turned on or experiences a spike in workload. By subjecting the PCB to these transient conditions, engineers can assess how quickly the board responds to thermal changes and whether there are any thermal stresses that could lead to component failures or damage to the PCB material over time. Overall, PCB thermal testing is an indispensable part of the PCB development process, enabling designers to optimize thermal designs and ensure the long - term reliability of electronic products.