-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-09-13 Views:1

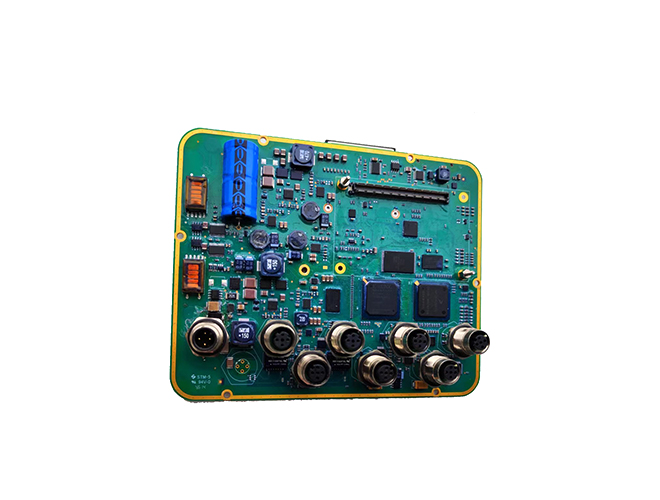

Printed Circuit Board (PCB) Surface Mount Technology (SMT) components have revolutionized the electronics manufacturing industry with their compact size, high - density assembly capabilities, and automated production suitability. SMT components are directly mounted onto the surface of the PCB, as opposed to the traditional through - hole method, eliminating the need for drilling holes in the board. This surface - mounting approach has significantly reduced the size and weight of electronic devices while enhancing their performance and reliability.

The range of SMT components is extensive, covering various types such as integrated circuits (ICs), resistors, capacitors, inductors, and diodes. SMT ICs, for instance, are available in a multitude of packages, including small - outline integrated circuits (SOICs), quad - flat no - lead (QFN) packages, and ball - grid array (BGA) packages. SOICs are commonly used for low - to - medium - pin - count devices and offer a relatively simple and cost - effective solution for surface - mounting. QFN packages provide better thermal performance and a smaller footprint, making them suitable for power - intensive and space - constrained applications. BGA packages, on the other hand, can accommodate a large number of pins in a compact area, enabling high - density interconnections and are widely used in advanced microprocessors and memory chips.

SMT resistors and capacitors are typically in the form of rectangular or cylindrical chips. They are available in different sizes, denoted by a two - digit code (e.g., 0402, 0603), where the numbers represent the length and width of the component in hundredths of an inch. Smaller sizes, like 0201 or 01005, are increasingly popular for ultra - compact electronic devices, such as wearable technology and mobile phones, where space is at a premium. These components are also highly accurate and have excellent electrical characteristics, ensuring stable performance in a wide range of operating conditions.

The manufacturing process of SMT components involves precise placement and soldering. Automated pick - and - place machines are used to accurately position the components on the PCB, which is pre - coated with solder paste. The PCB is then passed through a reflow oven, where the solder paste melts and forms a strong electrical and mechanical connection between the component and the PCB. This automated process allows for high - volume production with consistent quality and reduced labor costs. Overall, PCB SMT components have become the cornerstone of modern electronics manufacturing, enabling the development of smaller, faster, and more powerful electronic devices across various industries, from consumer electronics to aerospace and defense.