-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-10-27 Views:1

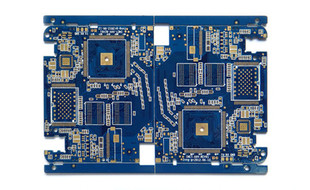

PCB circuit boards dedicated to X - ray machines are sophisticated and highly specialized components that play a fundamental role in the operation of these crucial medical imaging devices. X - ray machines rely on precise control of electrical signals, power management, and data processing to generate and manipulate X - ray beams for diagnostic purposes, and the PCB boards are designed to meet these exacting requirements.

At the heart of X - ray machine PCB boards is the power - control circuitry. X - ray generation requires high - voltage power supplies, often in the range of tens to hundreds of kilovolts. The PCB boards are equipped with advanced high - voltage generation and regulation circuits. These circuits are designed to convert the input electrical power into stable, high - voltage outputs with precise control over voltage levels and ripple. Specialized components, such as high - voltage transformers, rectifiers, and capacitors, are carefully integrated onto the PCB. High - voltage isolation techniques are employed to ensure safety and prevent electrical arcing or leakage, as any malfunction in the high - voltage system can lead to serious damage to the X - ray machine and pose risks to operators and patients.

Signal - processing circuits on X - ray machine PCB boards are also of critical importance. These circuits are responsible for controlling the timing and intensity of the X - ray pulses. They receive input signals from various control panels and sensors within the X - ray machine and generate the appropriate control signals for the X - ray tube. For example, the PCB board may incorporate pulse - width - modulation (PWM) circuits to precisely regulate the duration and amplitude of the X - ray pulses, enabling accurate imaging. Additionally, feedback - control loops are established to monitor and adjust the X - ray output based on real - time conditions, such as tube temperature and voltage stability.

Data - acquisition and communication functions are another key aspect of X - ray machine PCB boards. Modern X - ray machines are often connected to computer systems for image processing and storage. The PCB boards are designed with interfaces that can transmit the X - ray sensor data, including information about the X - ray beam characteristics and the detector responses, to the computer. High - speed serial communication protocols, such as USB 3.0, Ethernet, or PCI Express, are commonly integrated to ensure fast and reliable data transfer. Moreover, the PCB boards may also support communication with other peripheral devices, such as monitors, printers, and radiation - protection systems, facilitating seamless operation and coordination within the X - ray imaging setup.

The design of X - ray machine PCB boards also emphasizes reliability and durability. These devices operate in a challenging environment, often exposed to varying temperatures, vibrations, and electromagnetic interference. To ensure long - term reliable operation, high - quality components with high temperature - resistance and stability are selected. The PCB layout is optimized to minimize electromagnetic interference (EMI) and crosstalk between different circuits. Shielding techniques are applied to protect sensitive circuits from external EMI sources, and proper grounding strategies are implemented to ensure electrical safety and signal integrity. Overall, PCB circuit boards dedicated to X - ray machines are essential for enabling accurate, safe, and efficient X - ray imaging, contributing significantly to modern medical diagnosis and treatment.