-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-12-16 Views:1

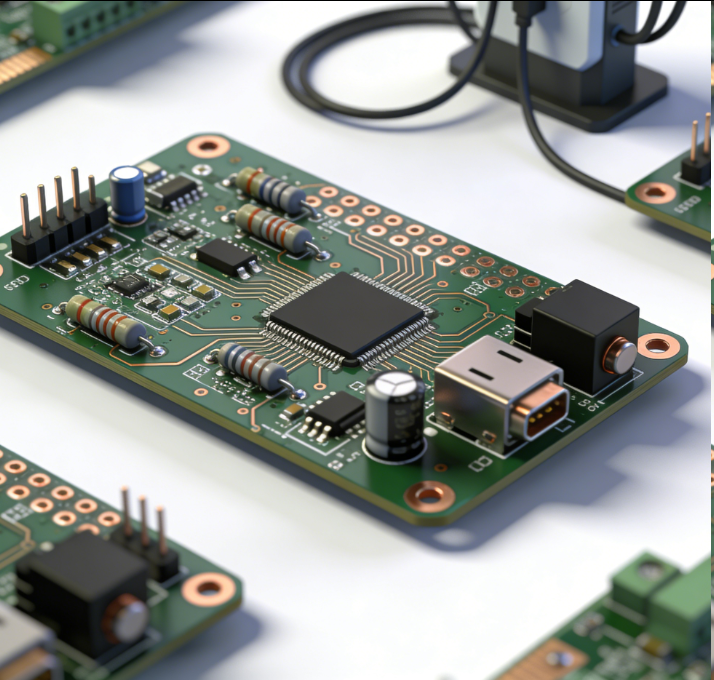

PCB circuit boards dedicated to charging piles are core components that manage power conversion, data communication, and safety protection for electric vehicle (EV) charging systems—critical for ensuring efficient, reliable, and safe charging. These PCBs are designed to handle high voltages (AC 220V/380V input, DC 200V–1000V output for fast charging) and high currents (up to 600A for ultra-fast chargers), requiring robust material selection and layout design.

Key functional modules on these PCBs include: a power conversion module (with IGBTs or SiC MOSFETs to convert AC to DC and regulate voltage/current), a communication module (supporting CAN, Ethernet, or 4G/5G for connecting to charging networks and EVs), and a safety protection module (with overvoltage, overcurrent, and leakage current detection circuits). To withstand high power dissipation, PCBs use high-Tg (glass transition temperature) FR-4 material (Tg ≥170°C) or ceramic substrates, and feature thick copper layers (2–4 oz) for efficient heat transfer.

Design considerations include electromagnetic compatibility (EMC) to avoid interference with grid signals, and waterproof/anti-corrosion coatings (e.g., conformal coating) for outdoor charging piles. For example, PCB boards for Tesla Superchargers integrate SiC-based power modules to reduce energy loss and enable 250kW fast charging. These PCBs are essential in residential, commercial, and public charging stations, ensuring EVs charge quickly while adhering to international safety standards (e.g., IEC 61851). For charging pile manufacturers, high-performance PCBs directly impact charging speed, energy efficiency, and long-term reliability.