-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-10-29 Views:1

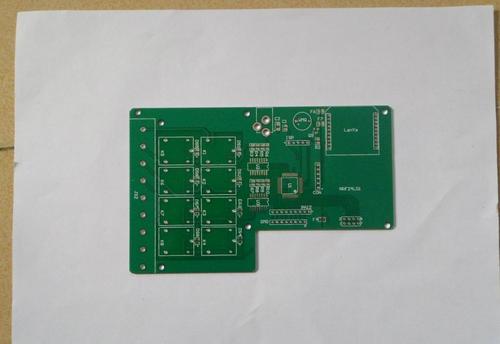

PCB boards for microbial detectors are pivotal components that enable the accurate and efficient identification and quantification of microorganisms in various samples. Microbial detection is essential in multiple fields, including healthcare, food safety, and environmental monitoring. These PCB boards are engineered with advanced electronics and specialized designs to support the complex processes involved in microbial analysis, ensuring reliable and precise results.

The design of PCB boards for microbial detectors commences with an in - depth understanding of the detection methods employed by these devices. Common techniques include polymerase chain reaction (PCR) - based methods, immunoassays, and fluorescence - based detection. For PCR - based microbial detectors, the PCB boards play a crucial role in controlling the temperature - cycling process, which is vital for the amplification of microbial DNA or RNA. They integrate sophisticated temperature - control circuits that interface with heating and cooling elements, along with high - precision temperature sensors. Microcontrollers on the PCB continuously monitor and adjust the temperature to maintain the optimal conditions for each stage of the PCR cycle, such as denaturation, annealing, and extension. Any deviation from the precise temperature profiles can lead to inaccurate amplification and, consequently, unreliable detection results.

In immunoassay - based microbial detectors, the PCB boards are responsible for signal processing. These detectors rely on the specific binding of antibodies to target microorganisms, and the resulting reactions generate electrical or optical signals. The PCB boards interface with sensors, such as electrochemical electrodes or photodetectors, to capture these weak signals. Amplifier circuits on the PCB enhance the signal strength, while analog - to - digital converters convert the analog signals into digital data for further analysis. Advanced signal - processing algorithms implemented on the PCB or in the detector's software are used to interpret the data accurately, distinguishing between positive and negative results and quantifying the amount of microorganisms present in the sample.

Electromagnetic compatibility (EMC) and noise reduction are of utmost importance in the design of PCB boards for microbial detectors. Given the sensitivity of the detection processes, even minute electromagnetic interference can disrupt the signal processing and lead to false - positive or false - negative results. To address this, the PCB design incorporates shielding and grounding techniques to minimize EMI. Multi - layer PCB designs are commonly utilized to separate different types of signals, power lines, and ground planes, reducing crosstalk between components. Additionally, high - quality, low - noise components are carefully selected to ensure the reliability of signal processing. The manufacturing of these PCB boards adheres to strict quality control standards, with each board undergoing comprehensive testing, including electrical testing, functional testing, and reliability testing, to guarantee accurate and consistent microbial detection.