-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-10-30 Views:1

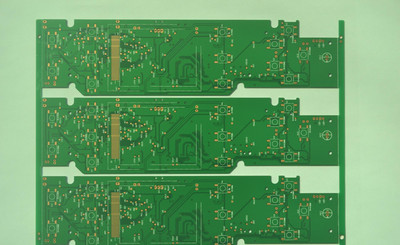

PCB boards for in vitro diagnostic (IVD) devices are indispensable components that underpin the accurate and efficient operation of these crucial medical instruments. IVD devices are used to analyze biological specimens, such as blood, urine, and tissue samples, outside the human body to aid in disease diagnosis, monitoring, and treatment. The PCB boards in IVD devices must be engineered with precision to handle complex electrical and signal processing tasks, ensuring reliable and consistent diagnostic results.

The design of PCB boards for IVD devices starts with a comprehensive understanding of the diverse functions these devices perform. IVD instruments often involve multiple processes, including sample collection, processing, detection, and data analysis. The PCB boards are responsible for coordinating and controlling these processes. They integrate a wide range of components, such as microcontrollers, sensors, amplifiers, and analog - to - digital converters (ADCs). Microcontrollers serve as the central processing units, managing the overall operation of the device, executing programmed instructions, and controlling the flow of data between different components. Sensors play a vital role in detecting specific biomarkers or analytes in the samples. For example, electrochemical sensors can measure the concentration of certain ions or molecules by converting chemical reactions into electrical signals. These weak electrical signals are then amplified by amplifier circuits on the PCB to enhance their strength before being converted into digital signals by ADCs for further processing and analysis.

Signal integrity and noise reduction are of paramount importance in IVD device PCB boards. Since the electrical signals generated during the diagnostic process are often very weak, even a small amount of noise can significantly affect the accuracy of the results. To address this, the PCB design incorporates advanced techniques such as proper grounding, shielding, and layout optimization. Multi - layer PCB designs are commonly used to separate different types of signals, power lines, and ground planes, reducing electromagnetic interference (EMI) and crosstalk between components. Additionally, high - quality components with low noise characteristics are selected to ensure the reliability of signal processing.

The manufacturing of PCB boards for IVD devices adheres to strict quality and regulatory standards. Given the critical nature of diagnostic results, any defect in the PCB can lead to inaccurate diagnoses, potentially having serious consequences for patient care. Each PCB undergoes rigorous testing, including electrical testing to check for short circuits, open circuits, and proper voltage and current flow; functional testing to verify that all components and functions are working correctly; and reliability testing to ensure the PCB can withstand various environmental conditions, such as temperature, humidity, and vibration. Moreover, the PCB boards must comply with international medical device regulations, such as those set by the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), to ensure their safety and effectiveness in clinical use. In summary, well - designed and precisely manufactured PCB boards are essential for the reliable operation of in vitro diagnostic devices, enabling accurate and timely medical diagnoses.