-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-12-20 Views:1

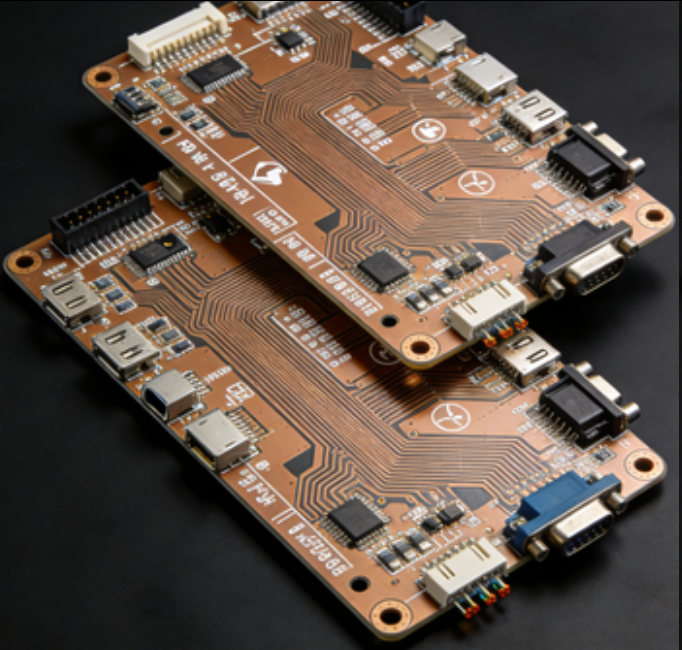

PCB boards for dental treatment equipment are specialized circuit boards designed to power and control dental devices like high-speed handpieces, dental curing lights, ultrasonic scalers, intraoral cameras, and digital radiography systems. Unlike consumer electronics PCBs, these boards must meet strict medical standards (e.g., IEC 60601-1 for electrical safety in medical devices) to ensure patient and operator safety—critical in dental settings where equipment interacts with patients’ oral tissues and may come into contact with bodily fluids. Dental equipment PCBs also require high reliability (24/7 operation in busy clinics) and resistance to harsh environmental factors like moisture, disinfectants (e.g., alcohol, hydrogen peroxide), and mechanical vibration (from handpiece operation).

Key design features of dental treatment equipment PCBs include:

Electrical Safety and Isolation: To prevent electric shock (a major risk in wet dental environments), PCBs use reinforced insulation (double or reinforced insulation layers) between primary (mains-powered) and secondary (patient-contacting) circuits. They comply with IEC 60601-1’s leakage current limits (<100μA for patient-contacting parts) and include ground fault circuit interrupters (GFCIs) to shut down power if leakage exceeds safe levels. For example, a dental curing light PCB separates the 110V/220V mains circuit from the LED driver circuit (which powers the curing light) using opto-isolators, ensuring no direct electrical path to the handpiece held by the dentist.

Resistance to Moisture and Disinfectants: Dental PCBs are coated with conformal coatings (e.g., Parylene C or epoxy) to seal against moisture, saliva, and disinfectants—preventing corrosion of copper traces and component leads. The board material (typically high-Tg FR-4 with Tg ≥170°C) is resistant to chemical degradation from frequent cleaning, and connectors are sealed (IP67-rated) to prevent fluid ingress. For intraoral camera PCBs (used inside the mouth), ultra-thin conformal coatings (5-10μm) maintain the board’s small form factor while providing full protection.

Precise Power Control for Specialized Functions: Dental devices require precise power regulation: high-speed handpieces need stable 12V DC power to maintain consistent rotation speed (300,000-400,000 RPM), while ultrasonic scalers rely on PCBs to generate 25-40kHz AC signals with adjustable amplitude (for removing tartar without damaging gums). PCBs integrate voltage regulators (e.g., LDO regulators for low-noise 5V power to sensors) and PWM controllers (for adjusting handpiece speed) to deliver accurate power. Digital radiography PCBs include high-voltage modules (up to 60kV) to power X-ray detectors, with feedback circuits to maintain voltage stability—critical for producing clear, consistent X-ray images.

Miniaturization and Integration: Dental equipment (e.g., portable curing lights, handheld intraoral cameras) requires compact PCBs to fit into small form factors. Surface-mount technology (SMT) components (0402 or 0201 size resistors/capacitors) and multi-layer PCBs (4-8 layers) reduce board size while increasing component density. For example, an intraoral camera PCB (typically 50mm×30mm) integrates an image sensor, LED driver, wireless transmitter (for sending images to a computer), and battery management circuit—all on a single board.

Compliance and certification are critical: dental PCBs must pass IEC 60601-1-2 (EMC immunity for medical devices) to avoid interference from other clinic equipment (e.g., X-ray machines), and RoHS compliance to restrict hazardous substances. Regular testing (temperature cycling, humidity testing, chemical resistance) ensures long-term reliability. By meeting these standards, dental treatment equipment PCBs enable safe, efficient dental procedures—from routine cleanings to complex restorative work.