-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-08-09 Views:1

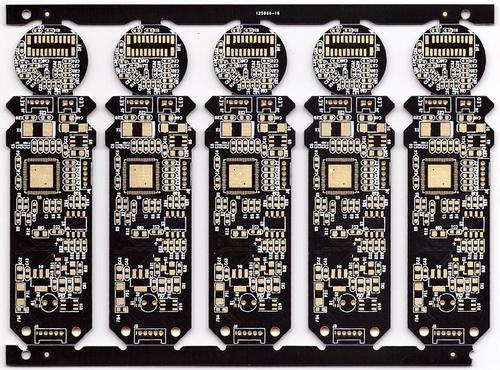

PCB blind and buried via fabrication is a sophisticated technique used in multi-layer printed circuit boards (PCBs) to create electrical connections between specific layers without penetrating the entire board, enhancing design density and reducing signal interference. Blind vias connect an outer layer to one or more inner layers but do not reach the opposite outer layer, while buried vias link two or more inner layers, remaining entirely hidden within the board. This approach is critical for high-density PCBs in applications like smartphones, medical devices, and aerospace electronics, where miniaturization and signal integrity are paramount.

The fabrication process begins with drilling, using laser or mechanical methods. Laser drilling is preferred for small vias (typically 50-150 μm in diameter) due to its precision, while mechanical drilling is used for larger sizes. After drilling, the vias undergo desmearing to remove resin residue, ensuring proper adhesion of conductive materials. The next step is metallization, where a thin layer of copper is deposited on the via walls using electroless copper plating, creating a conductive path. This is followed by electrolytic copper plating to thicken the copper layer, ensuring reliable electrical conductivity.

For multi-layer boards, alignment is critical during lamination to ensure vias connect the correct layers. Manufacturers use optical alignment systems with registration marks to achieve precision within ±5 μm. After lamination, the outer layers are processed with additional drilling (for through-vias if needed), plating, and etching to form the final circuit pattern. Testing, including via continuity checks and insulation resistance measurements, ensures each via meets electrical specifications. PCB blind and buried via fabrication requires advanced equipment and strict process control, but it enables the creation of compact, high-performance boards that meet the demands of modern electronic devices.