-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-08-14 Views:1

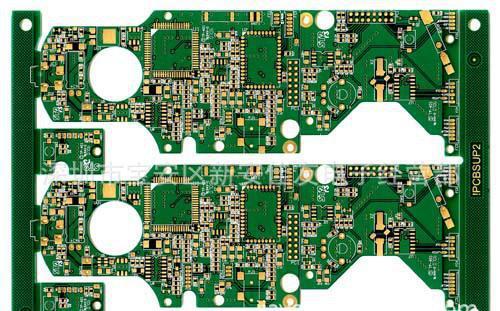

https://www.chengchipcba.com/industry_news/Introduction-to-AOI-Automated-Optical-Inspection_460.htmlPCB automated production refers to the use of advanced machinery, robotics, and computer-controlled systems to manufacture printed circuit boards (PCBs) with minimal human intervention. This streamlined approach encompasses every stage of PCB fabrication, from design validation and material preparation to etching, drilling, and final assembly, ensuring high precision, consistency, and efficiency. Automated production is crucial for meeting the demands of modern electronics, where PCBs are increasingly complex, miniaturized, and required in large volumes.

One of the key advantages of automated PCB production is its ability to maintain tight tolerances. Computer-aided design (CAD) files are directly translated into machine instructions, guiding automated routers and laser drills to create holes and traces with accuracies as fine as ±0.01mm. This precision is essential for PCBs with high component densities, such as those used in smartphones or medical devices, where even minor errors can lead to short circuits or signal interference. Automated optical inspection (AOI) systems further enhance quality by scanning each PCB for defects—such as misaligned traces, missing vias, or contamination—immediately after fabrication, allowing for real-time adjustments and reducing the risk of faulty boards reaching the next production stage.

Efficiency is another hallmark of automated production. Robotic arms handle material loading and unloading, while conveyor systems transport PCBs between processing stations, minimizing downtime between steps. For example, in the etching phase, automated tanks precisely control chemical concentrations and immersion times, ensuring uniform removal of copper from non-conductive areas. This consistency not only improves product quality but also reduces material waste, as automated systems optimize the use of copper clad laminates and etching chemicals. High-volume production lines can manufacture thousands of PCBs per day, far exceeding the output of manual or semi-automated processes.

Flexibility is a surprising benefit of modern automated PCB production. While traditional manual setups require extensive retooling for different PCB designs, automated systems can quickly switch between production runs using programmable parameters. This adaptability is critical for industries with diverse product lines, such as automotive electronics, where PCBs for infotainment systems, sensors, and control modules may vary significantly in size and complexity. Automated systems also support rapid prototyping, allowing manufacturers to produce small batches of custom PCBs for testing before scaling up to mass production.

Traceability is enhanced in automated production through the use of barcode or RFID tracking. Each PCB is assigned a unique identifier, enabling manufacturers to log data at every stage—from material batch numbers to processing times and inspection results. This data is stored in centralized systems, facilitating quality control audits, regulatory compliance, and root-cause analysis in case of defects. For industries with strict standards, such as aerospace or medical devices, this level of traceability is indispensable for ensuring product reliability and safety.

PCB automated production revolutionizes electronics manufacturing by combining precision, efficiency, flexibility, and traceability. By minimizing human error and leveraging advanced technology, it enables the production of high-quality, complex PCBs at scale, meeting the needs of a rapidly evolving electronics market.