-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-08-25 Views:1

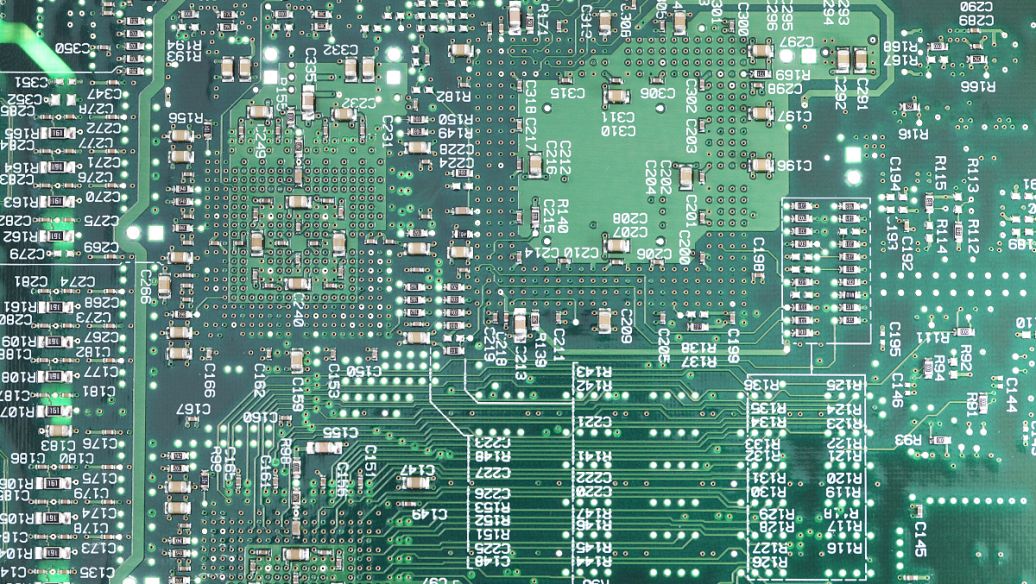

PCB AOI (Automatic Optical Inspection) is a sophisticated quality control technology used in printed circuit board (PCB) manufacturing to detect defects and inconsistencies in PCBs during or after production. This automated system utilizes high-resolution cameras, advanced lighting techniques, and image processing software to visually inspect PCBs with remarkable speed and accuracy, far surpassing manual inspection capabilities.

The core functionality of AOI lies in its ability to compare the image of a tested PCB against a preprogrammed "golden sample" or a digital design file (such as CAD data). The system captures detailed images of the PCB from multiple angles using specialized lighting—including white light, colored light, and directional lighting—to highlight different types of defects. Common defects detected by AOI include missing components, incorrect component placement, solder bridges, insufficient solder, excess solder, tombstoning (components standing upright), scratches, and stains on the PCB surface.

AOI systems are integrated into various stages of PCB production, including after solder paste application (to check for correct paste deposition and alignment), after component placement (to verify accurate positioning), and after soldering (to inspect solder joint quality). This in-line inspection allows manufacturers to identify and address issues early in the production process, reducing the number of defective PCBs that proceed to later stages and minimizing rework costs.

One of the key advantages of AOI is its speed. Modern AOI systems can inspect a standard PCB in a matter of seconds, making them suitable for high-volume production lines where throughput is critical. Additionally, AOI provides consistent and objective results, eliminating the variability and fatigue associated with manual inspection. This consistency ensures that defects are detected reliably, improving overall product quality and reducing the risk of field failures.

AOI technology continues to evolve with advancements in artificial intelligence (AI) and machine learning. AI-powered AOI systems can learn from historical data to recognize new or complex defects, improving detection accuracy over time. They can also adapt to variations in PCB designs and manufacturing processes, making them more flexible and versatile.

PCB AOI inspection is an indispensable tool in modern PCB manufacturing, ensuring high-quality standards, reducing production costs, and enhancing the reliability of electronic devices that rely on PCBs. Its ability to detect defects quickly and accurately makes it a cornerstone of quality control in the electronics industry.