-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-11-04 Views:1

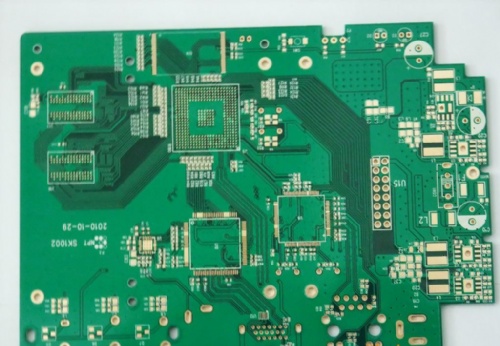

One-stop PCBA manufacturing integrates all stages of printed circuit board assembly—from PCB design review, component sourcing, and fabrication to assembly, testing, and even post-production services like conformal coating—into a single, streamlined service. This model eliminates the need for clients to coordinate with multiple vendors (e.g., separate PCB fabricators, component distributors, and assembly houses), reducing project complexity, shortening lead times, and minimizing the risk of miscommunication or compatibility issues.

The core value of one-stop manufacturing lies in its end-to-end integration and accountability. The process typically begins with design for manufacturing (DFM) review: engineers from the one-stop provider assess the client’s PCB design to identify potential issues (e.g., incompatible component footprints, insufficient trace width for current demands, or poor thermal management) and suggest optimizations before production starts. This proactive step reduces rework rates by 30–50% compared to fragmented services.

Next, component sourcing leverages the provider’s global supply chain networks and bulk purchasing power. They source authentic components from authorized distributors (e.g., Digi-Key, Mouser) to avoid counterfeits, and can even secure hard-to-find or obsolete parts through specialized channels. For clients with bill-of-materials (BOM) challenges (e.g., component shortages), the provider offers alternative part recommendations that meet performance requirements.

PCB fabrication and assembly are executed in-house or through trusted, integrated partners, ensuring consistent quality control. The provider manages all logistics—from transporting PCBs to the assembly line to delivering finished PCBA units—and provides real-time project tracking, allowing clients to monitor progress remotely.

Post-assembly stages include comprehensive testing (e.g., functional testing, in-circuit testing, X-ray inspection for BGA joints) and value-added services like conformal coating (to protect PCBs from moisture or dust) and packaging. For high-volume orders, the provider may also offer warehousing and just-in-time (JIT) delivery to optimize the client’s inventory management.

One-stop PCBA manufacturing is ideal for startups, small-to-medium enterprises (SMEs), and companies with limited in-house manufacturing resources. It reduces project lead times by 20–40% (e.g., a 500-unit batch that takes 4 weeks with fragmented services can be completed in 2–3 weeks with one-stop service) and lowers overall costs by eliminating vendor coordination fees and reducing the risk of errors from design to delivery.