-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-07-24 Views:1

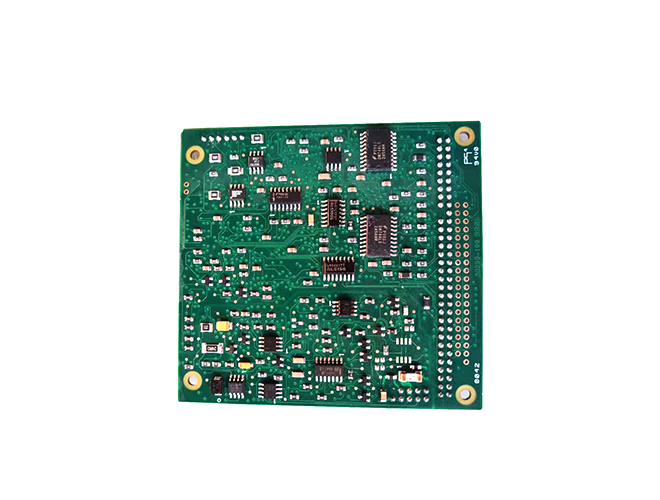

Designing rigid PCB boards for high-temperature environments requires careful selection of materials, structural optimization, and thermal management strategies to ensure reliable performance under extreme heat. The primary challenge is to withstand prolonged exposure to temperatures exceeding 125°C, common in industrial ovens, automotive engine compartments, and aerospace systems.

Material selection is critical. Traditional FR-4 epoxy resin substrates, which typically degrade above 130°C, are replaced with high-temperature alternatives such as polyimide (PI) or cyanate ester resins, which can tolerate continuous use at 150–200°C. Conductive materials also matter: copper clad laminates with thicker copper layers (2–3 oz) enhance heat dissipation, while nickel-gold plating on pads resists oxidation at high temperatures, maintaining solder joint integrity. For solder masks, UV-curable or epoxy-based masks with high glass transition temperatures (Tg) above 170°C prevent cracking or delamination.

Structural design focuses on minimizing thermal stress. Using a symmetric layer stack-up balances thermal expansion, reducing warpage when the PCB heats up. Large ground planes and power planes act as heat spreaders, distributing heat evenly across the board. Thermal vias—small plated holes connecting top and bottom layers—channel heat from hot components (e.g., power transistors) to the opposite side, where heat sinks can be attached. Component placement is optimized to separate heat sources: high-power devices are spaced apart to prevent hotspots, while temperature-sensitive components (e.g., sensors, capacitors) are placed in cooler areas or shielded with thermal barriers.

Testing is essential to validate performance. Thermal cycling tests (-55°C to 150°C for 1000+ cycles) simulate real-world conditions, checking for solder joint fatigue or trace cracking. IR thermography identifies hotspots, guiding further design tweaks. By integrating these measures, rigid PCBs can maintain electrical performance, mechanical stability, and long-term reliability in high-temperature environments.