-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-08-04 Views:1

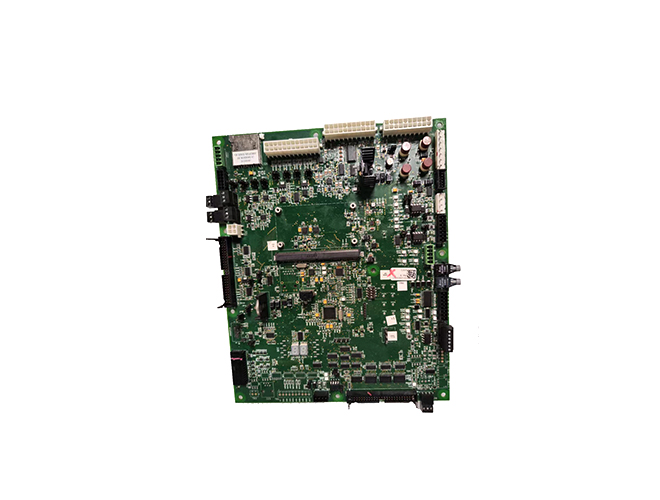

High-precision CNC milling is a critical manufacturing step in rigid printed circuit board (PCB) production, enabling the creation of intricate shapes, precise cutouts, and accurate edge finishes. This process involves the use of computer-controlled milling machines equipped with diamond-tipped or carbide tools to remove material from the rigid PCB substrate—typically fiberglass-reinforced epoxy (FR-4)—with exceptional accuracy, often achieving tolerances as tight as ±0.02 mm.

The process begins with CAD/CAM design translation, where the PCB’s layout files (Gerber or ODB++) are converted into machine-readable code. This code dictates tool paths, spindle speeds, and feed rates, ensuring that each cut aligns with the design specifications. Rigid PCBs, due to their structural rigidity, require stable fixturing to prevent vibration during milling, which can cause dimensional errors or tool wear. Vacuum clamping systems are commonly used to secure the PCB firmly to the machine bed, minimizing movement even at high cutting speeds.

Tool selection is paramount to achieving high precision. Carbide tools are preferred for their durability when machining FR-4, while diamond tools are used for ultra-fine finishes, such as those required in high-frequency PCBs where surface smoothness impacts signal integrity. The milling parameters are carefully calibrated: spindle speeds range from 15,000 to 60,000 RPM, and feed rates are adjusted based on the material thickness and tool diameter to balance efficiency and precision. For example, a 1 mm diameter tool might operate at a feed rate of 50–100 mm/min to avoid excessive tool load.

Post-milling steps include deburring and cleaning to remove residual copper particles and debris, which could interfere with subsequent assembly processes like soldering. Inspection using coordinate measuring machines (CMM) or optical scanners verifies that the milled features meet dimensional requirements. This level of precision is critical for rigid PCBs used in applications such as aerospace electronics, medical devices, and industrial control systems, where misalignments could lead to electrical shorts or mechanical failures.

Advancements in CNC technology, such as multi-axis machining, have further enhanced capabilities, allowing for complex 3D features and undercuts in rigid PCBs. Additionally, adaptive control systems can adjust parameters in real-time based on sensor feedback, optimizing tool performance and extending tool life. High-precision CNC milling thus remains indispensable in ensuring the functionality and reliability of rigid PCBs in high-performance electronic systems.