-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-07-03 Views:1

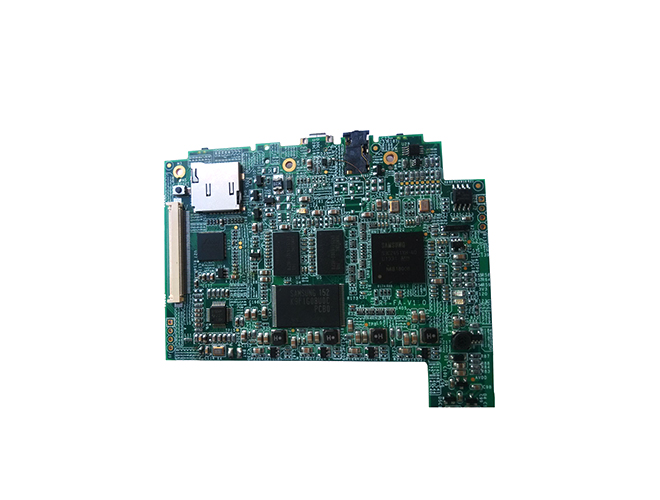

Green oil (solder mask) bridges are critical in double-sided PCB design to prevent electrical short circuits between adjacent traces, especially in high-voltage or high-density layouts. The “green oil bridge” refers to the insulating layer of solder mask that separates conductive paths on the same layer or between layers via vias. Proper design ensures reliability by controlling creepage and clearance distances, which are governed by industry standards (e.g., IPC-2221).

Key design principles include:

Clearance Calculation: Determine minimum spacing between traces based on voltage (e.g., 1 kV requires ~2 mm clearance in air). Solder mask adds an additional insulation layer, but its effectiveness depends on thickness (typically 25–50 μm).

Via Coverage: Vias connecting top and bottom layers must be fully covered with solder mask to prevent moisture ingress or accidental contact. “Covered vias” (mask over the via) or “filled vias” (with conductive or non-conductive material) are common techniques.

Thermal Considerations: In power-intensive designs, green oil bridges must withstand high temperatures without cracking. High-Tg solder masks (e.g., Tg > 150°C) are preferred for reflow soldering and long-term reliability.

Manufacturing Feasibility: Solder mask resolution limits the minimum bridge width. Most fabricators can achieve 50–75 μm gaps, but tight designs (e.g., <25 μm) may require laser imaging or specialized processes.

For example, in motor control circuits on double-sided PCBs, green oil bridges separate high-voltage traces (e.g., 240V AC) from low-voltage control signals (5V DC), preventing arcing. In automotive PCBs, bridges must endure vibration and temperature cycles, so robust solder mask materials (e.g., epoxy-based) with high adhesion to copper are essential. Designers should also avoid “green oil dams” that trap flux during soldering, which can cause voids or delamination.