-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-07-15 Views:1

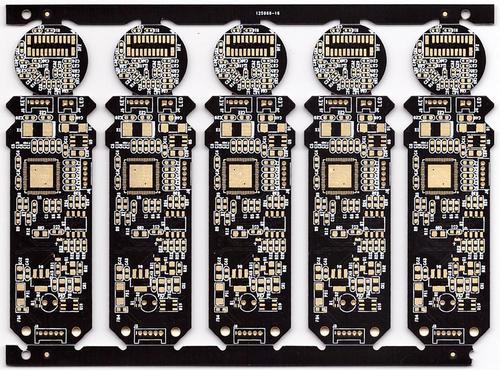

The electrical stability of rigid printed circuit boards (PCBs) is critical for ensuring reliable performance in electronic devices, as any degradation can lead to signal loss, short circuits, or complete system failure. Several key factors influence this stability, ranging from material selection and design choices to manufacturing processes and environmental conditions.

Material properties play a foundational role. The substrate material, typically fiberglass-reinforced epoxy (FR-4), must exhibit consistent dielectric constant (Dk) and dissipation factor (Df) across operating frequencies. Variations in Dk can cause signal impedance mismatches, leading to reflections and signal distortion, especially in high-frequency applications like 5G devices or radar systems. Additionally, the copper cladding thickness and purity affect conductivity—thicker copper (e.g., 1 oz vs. 0.5 oz) reduces resistance but increases weight, while impurities in copper can create localized hotspots and increase signal loss.

Design parameters are equally influential. Trace width and spacing determine current-carrying capacity and crosstalk: narrower traces increase resistance, potentially causing voltage drops, while insufficient spacing between adjacent traces can lead to capacitive coupling, where signals interfere with each other. Via design is another critical factor—poorly plated vias (used to connect layers in multi-layer PCBs) introduce resistance and inductance, disrupting signal integrity. Ground plane design, such as using a solid ground layer, helps mitigate noise by providing a low-impedance return path for signals, enhancing stability in high-speed circuits.

Manufacturing processes also impact electrical stability. Uneven etching during trace formation can create irregularities in conductor width, leading to impedance variations. Over-etching may thin traces, increasing resistance, while under-etching can leave unwanted copper, risking short circuits. Lamination pressure and temperature control during multi-layer PCB fabrication ensure proper bonding between layers, preventing delamination that could introduce air gaps (which have high dielectric strength) and disrupt signal paths. Additionally, solder mask application quality matters—pinholes in the mask can expose copper to corrosion, altering conductivity over time.

Environmental conditions such as temperature, humidity, and chemical exposure further affect stability. High temperatures can cause substrate materials to expand, changing trace spacing and impedance, while humidity can lead to moisture absorption in the substrate, increasing Df and promoting electrochemical migration (the growth of conductive filaments between traces, causing shorts). Exposure to corrosive gases (e.g., sulfur dioxide in industrial environments) can oxidize copper traces, increasing resistance.

In summary, the electrical stability of rigid PCBs is a result of careful material selection, precise design, controlled manufacturing, and protection against environmental stressors. Addressing these factors ensures consistent performance across the device’s lifecycle.