-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-05-30 Views:1

Designing a calculator circuit on a single - sided printed circuit board (PCB) presents unique challenges and opportunities. Single - sided PCBs have components and traces on only one side, which requires careful planning and optimization to fit all the necessary elements of a calculator circuit while ensuring proper functionality and electrical performance.

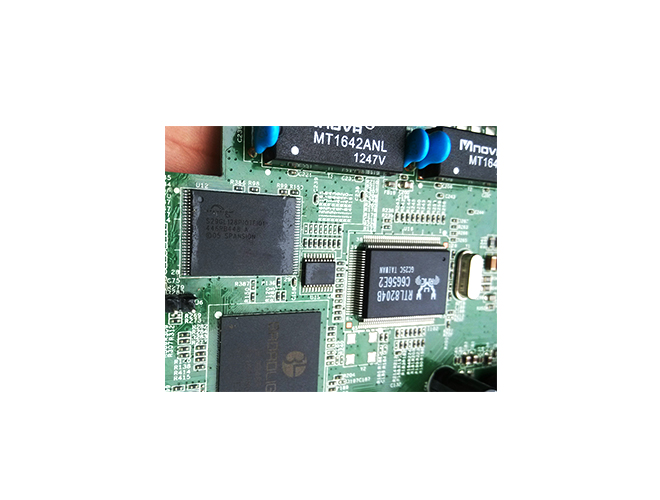

The first step in the design process is to define the requirements of the calculator. This includes determining the arithmetic operations it can perform (such as addition, subtraction, multiplication, and division), the number of digits it can display, and any additional features like memory functions or scientific calculations. Based on these requirements, the necessary components are selected, including a microcontroller or a dedicated calculator integrated circuit (IC), display elements (such as liquid crystal displays or light - emitting diodes), buttons for user input, resistors, capacitors, and other passive components.

Once the components are selected, the layout design of the single - sided PCB begins. The layout is a crucial aspect as it determines how the components are placed and how the traces are routed to connect them. Since there is only one side available for traces, avoiding crossing traces becomes a significant challenge. To overcome this, designers often use techniques such as bending traces, using jumper wires (if necessary), and carefully arranging the components to minimize the need for trace crossovers. The microcontroller or calculator IC is usually placed at the center or a strategic location on the PCB, as it is the core component that controls the overall operation of the calculator. The display elements are positioned in a way that is convenient for the user to read, and the buttons are placed in an intuitive layout for easy input.

Routing the traces requires precise planning to ensure proper electrical connectivity. The traces need to be wide enough to handle the required current without excessive resistance, and they should be routed away from sensitive components to avoid electromagnetic interference. For example, traces carrying high - frequency signals should be kept away from the display and button circuits. In addition, power and ground traces are designed to be as short and wide as possible to reduce voltage drops and noise.

After the layout is designed, it is converted into a manufacturing - ready format, typically using PCB design software. The software generates the Gerber files, which contain all the information needed to manufacture the PCB, such as the trace patterns, drill holes, and component placement. These files are then sent to a PCB manufacturer for production. Once the single - sided PCB is manufactured, the components are soldered onto it, and the calculator circuit is assembled. Finally, the assembled calculator is tested thoroughly to ensure that it functions correctly, performing all the specified arithmetic operations accurately and responding properly to user inputs. Designing a calculator circuit on a single - sided PCB requires a combination of electrical engineering knowledge, creative layout design skills, and attention to detail to create a functional and reliable product.