-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-11-28 Views:1

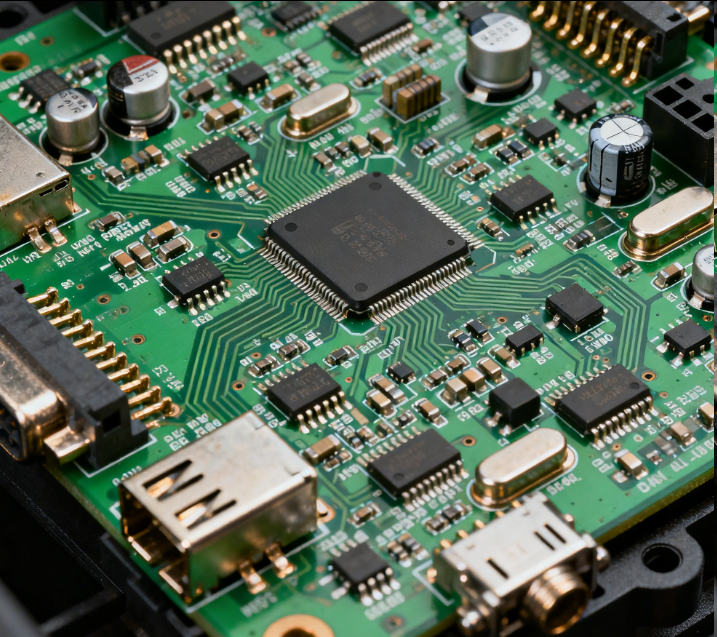

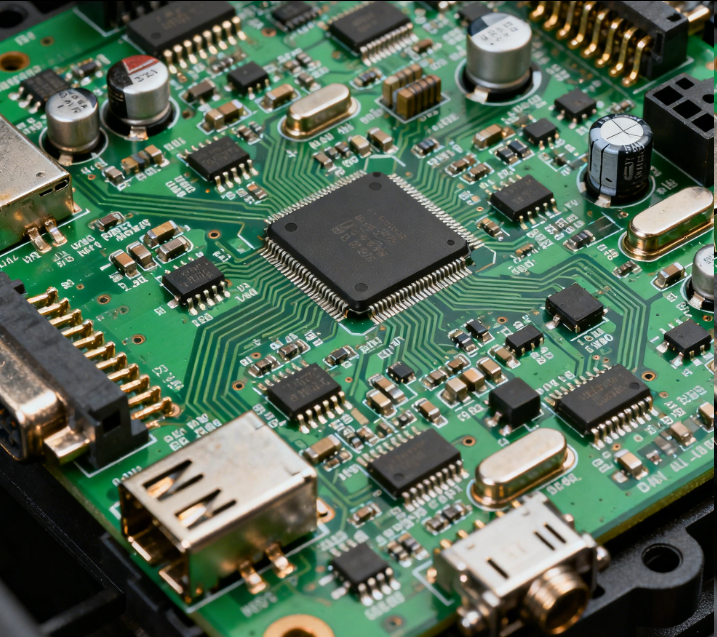

Automotive Central Control PCBA is a specialized Printed Circuit Board Assembly designed to serve as the core of a vehicle’s infotainment and control system—integrating functions like touchscreen display, audio playback, navigation, climate control, and vehicle status monitoring. Unlike consumer electronics PCBA, it must meet strict automotive industry standards (e.g., IATF 16949, AEC-Q100) for reliability, temperature resistance, and electromagnetic compatibility (EMC), as it operates in harsh in-vehicle environments (temperature fluctuations from -40°C to 85°C, vibration, and electrical noise). This PCBA is a critical component in modern vehicles, bridging the gap between driver experience and vehicle functionality.

The core technical characteristics of Automotive Central Control PCBA include multi-functional integration and automotive-grade component selection. To support diverse features, it integrates high-performance microprocessors (MPUs) such as Qualcomm’s Snapdragon Automotive Cockpit Platform or NVIDIA’s Tegra series—these chips handle complex tasks like 4K display rendering, voice recognition, and multi-tasking with clock speeds up to 2.8 GHz. The PCBA also includes dedicated modules for connectivity: Bluetooth (for phone pairing), Wi-Fi (for over-the-air updates), GPS (for navigation), and CAN/LIN bus interfaces (to communicate with other vehicle systems like the engine control unit or dashboard). For infotainment, it features audio codecs (from companies like Cirrus Logic) for high-quality sound and display controllers to drive large touchscreens (10–15 inches common in modern vehicles).

Design considerations for Automotive Central Control PCBA focus on reliability, EMC compliance, and user experience. Reliability is ensured by using AEC-Q100 Grade 2 or 3 components (rated for -40°C to 105°C) and implementing robust soldering processes to withstand vibration (meeting ISO 16750-3 standards). EMC compliance is critical—vehicles have dense electrical systems, so the PCBA uses shielding (e.g., copper cans around sensitive components) and filter circuits to prevent interference with radio signals or other vehicle electronics. User experience-driven design includes low-latency touch response (under 100ms) and thermal management to avoid overheating near the driver’s cabin, which could cause discomfort or performance throttling.

Practical applications of Automotive Central Control PCBA define the modern driving experience. In passenger cars, it powers touchscreen infotainment systems that let drivers access music, navigation, and smartphone apps hands-free (via Apple CarPlay or Android Auto). In luxury vehicles, it may integrate advanced features like gesture control, heads-up display (HUD) synchronization, or rear-seat entertainment control. It also acts as a gateway for vehicle status updates, displaying fuel levels, tire pressure, and maintenance alerts. While Automotive Central Control PCBA has higher development costs due to automotive certification, its role in enhancing driver comfort and connectivity makes it indispensable. For any automaker, a well-designed central control PCBA is key to delivering a competitive, user-friendly vehicle interior.