-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-07-04 Views:1

PCBs play a vital role in 5G base station equipment, enabling the high - speed data transmission and complex signal processing required by the fifth - generation wireless technology.

In 5G base stations, high - frequency PCBs are used in radio frequency (RF) front - end modules. These PCBs need to handle frequencies ranging from sub - 6 GHz to millimeter - wave (mmWave) bands, typically up to 28 GHz or higher. Specialized materials with low dielectric loss tangent (Df) and stable dielectric constant (Dk) are required to minimize signal attenuation and distortion. For example, Rogers RT/duroid and Isola FR408HR materials are commonly used in 5G RF PCBs.

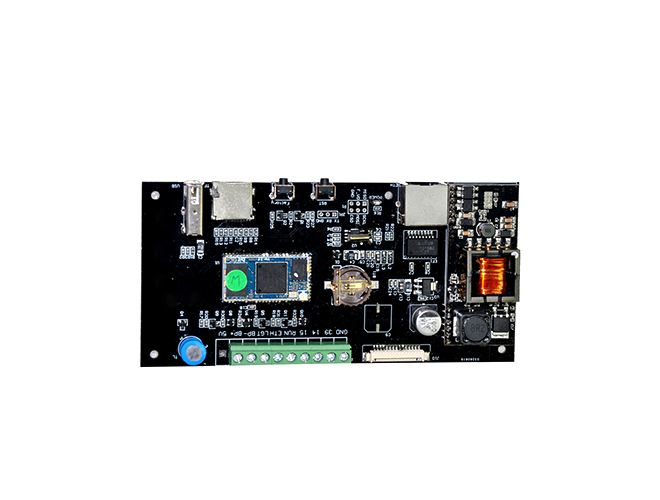

Multilayer PCBs with high - density interconnects are employed in baseband processing units. These units handle digital signal processing, modulation, and demodulation tasks. The large number of input/output (I/O) connections and high - speed data buses demand boards with fine - pitch traces and microvias to reduce signal delay and crosstalk.

Power management is also a crucial aspect in 5G base stations. PCBs in power supply units need to handle high currents efficiently while maintaining electrical isolation and thermal management. They often feature thick copper layers and power planes to reduce resistive losses and distribute power evenly across the board.

Moreover, the miniaturization trend in 5G base stations requires PCBs with smaller form factors and higher integration levels. Advanced packaging techniques, such as system - in - package (SiP) and integrated fan - out (InFO), are increasingly being used in conjunction with PCBs to further reduce the overall size and improve performance.