-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-07-02 Views:1

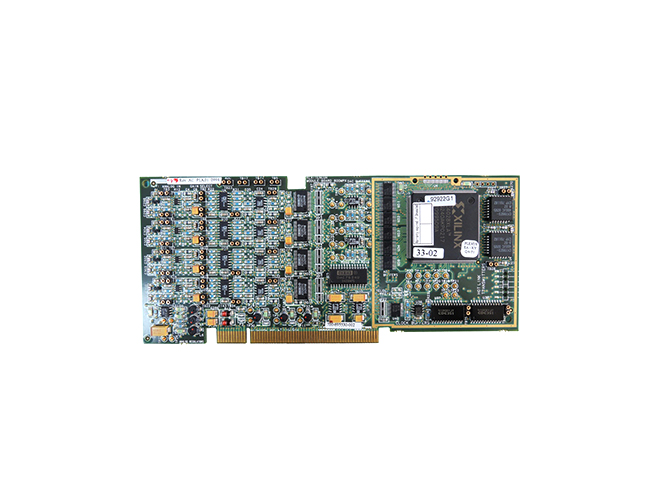

Multilayer PCBs have become indispensable in automotive electronic control systems due to their ability to meet the stringent requirements of modern vehicles, such as high reliability, compact size, and complex functionality. These boards are used in various automotive applications, including engine control units (ECUs), body control modules, infotainment systems, and advanced driver-assistance systems (ADAS).

In engine control units, multilayer PCBs play a crucial role in managing and controlling the engine's performance. They need to handle a large number of input signals from sensors (such as temperature sensors, pressure sensors, and oxygen sensors) and generate precise control signals for actuators (such as fuel injectors and ignition coils). The complex signal routing and power management requirements of ECUs are effectively met by multilayer PCBs. These boards can have multiple layers for separating different types of signals (analog, digital, and power) to reduce interference and ensure accurate operation. Additionally, the high density of components and traces on multilayer PCBs allows for a more compact design, which is essential for fitting the ECU into the limited space available in the engine compartment.

For body control modules, which are responsible for controlling various electrical functions in the vehicle such as lighting, door locks, and window regulators, multilayer PCBs provide a reliable platform. They can integrate multiple functions onto a single board, reducing the number of separate components and wiring harnesses. This not only simplifies the vehicle's electrical system but also improves its reliability by minimizing the potential points of failure. The ability of multilayer PCBs to withstand the harsh automotive environment, including vibrations, temperature variations, and electrical noise, is also crucial for the long-term operation of body control modules.

In infotainment systems, multilayer PCBs are used to support high-definition displays, audio processing, and connectivity features. They need to handle high-speed data signals for video and audio transmission, as well as interface with various external devices such as smartphones and navigation systems. The design of multilayer PCBs for infotainment systems focuses on signal integrity and impedance matching to ensure high-quality audio and video output. Moreover, the compact size and lightweight nature of multilayer PCBs are beneficial for designing sleek and space-efficient infotainment consoles.

Advanced driver-assistance systems, such as adaptive cruise control, lane departure warning, and automatic emergency braking, rely on multilayer PCBs to process data from multiple sensors (such as cameras, radar, and lidar). These systems require fast and accurate signal processing, and the multilayer structure of PCBs allows for efficient routing of high-speed digital signals. The reliability of multilayer PCBs is of utmost importance in ADAS, as any failure in the PCB can lead to a malfunction of the safety-critical system. Therefore, strict quality control measures are implemented during the manufacturing of PCBs for automotive applications to ensure their performance and reliability over the vehicle's lifespan.