-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-07-03 Views:1

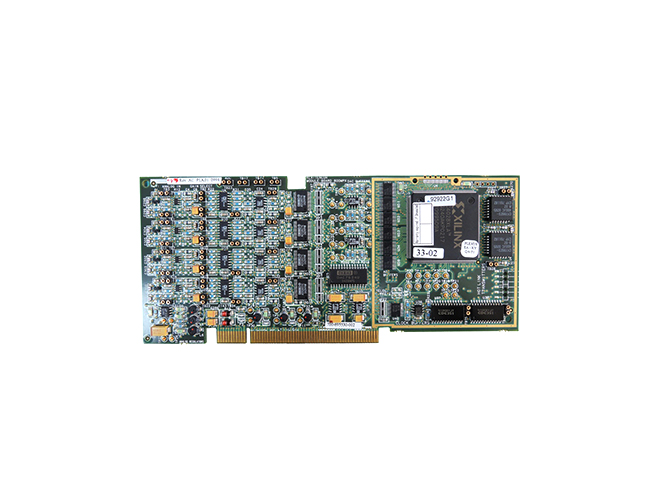

Double-layer PCBs are widely used in smart sweeper robots due to their balance of cost, complexity, and functionality. These boards integrate multiple subsystems, including motor control, sensor interfaces, wireless communication, and power management, while maintaining a compact form factor suitable for the sweeper’s limited internal space.

Key applications include:

Motor Control: The main brushless DC (BLDC) motor and side brush motors require H-bridge drivers and current sensing circuits. Double-layer boards route power traces (high current) on one layer and control signals (low voltage) on the other, minimizing noise coupling. Thermal vias in the power layer dissipate heat from MOSFETs.

Sensor Integration: Infrared (IR) proximity sensors, cliff detectors, and collision sensors are distributed across the board. The bottom layer often hosts ground planes to shield analog sensor signals from digital noise. For example, IR emitters and receivers are placed on the bottom edge of the PCB to detect obstacles, with traces routed around the board’s perimeter.

Wireless Communication: Bluetooth or Wi-Fi modules (e.g., ESP32) require controlled-impedance traces for antenna signals. Double-layer boards use the top layer for RF traces and the bottom layer as a solid ground plane to ensure signal integrity, avoiding the complexity of multilayer RF designs.

Power Management: Battery charging circuits (e.g., Li-ion chargers) and voltage regulators are centralized on one layer for easy thermal management. The opposite layer routes low-power signals (e.g., MCU control lines) and includes decoupling capacitors near power pins to reduce ripple.

A typical smart sweeper PCB might measure 100 x 80 mm, with the top layer featuring components like the MCU (e.g., STM32), motor drivers, and sensors, while the bottom layer includes the ground plane, power traces, and passive components. Designers must prioritize noise isolation: separating analog (sensor) and digital (MCU) ground planes, and using ferrite beads to filter power lines. Double-layer boards also enable cost-effective mass production, critical for consumer electronics where bill-of-materials (BOM) costs are tightly controlled.