-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-10-21 Views:1

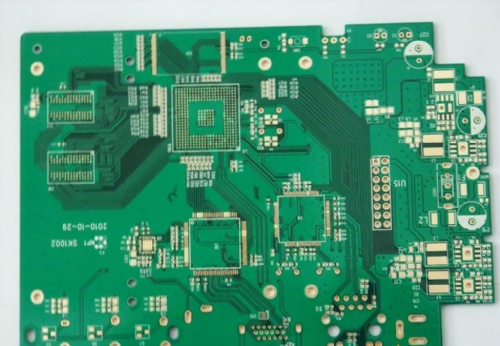

Pressure sensor adapted PCB (Printed Circuit Board) boards are crucial components that facilitate the seamless integration and optimal performance of pressure sensors in various applications. These PCB boards are specifically designed to meet the unique requirements of pressure sensors, ensuring accurate signal acquisition, processing, and transmission.

The design of pressure sensor adapted PCB boards begins with a deep understanding of the pressure sensor's characteristics. Different types of pressure sensors, such as piezoresistive, capacitive, and piezoelectric sensors, have distinct electrical and mechanical properties. For piezoresistive pressure sensors, which change their resistance in response to pressure, the PCB board needs to be designed with precise impedance - matching circuits. This helps in accurately converting the resistance changes into measurable electrical signals. Capacitive pressure sensors, on the other hand, rely on changes in capacitance. The PCB board for these sensors incorporates specialized capacitance - to - voltage conversion circuits to ensure accurate signal processing.

Signal conditioning is a key aspect of pressure sensor adapted PCB boards. Since the signals generated by pressure sensors are often weak and susceptible to noise interference, the PCB board is equipped with amplifiers, filters, and analog - to - digital converters (ADCs). Amplifiers boost the weak sensor signals to a suitable level for further processing. Filters, such as low - pass filters, are used to remove high - frequency noise, ensuring that only the relevant pressure - related signals are retained. ADCs convert the analog signals from the sensors into digital format, making them compatible with digital processing systems and microcontrollers.

In addition to signal processing, the layout of the PCB board is carefully planned to minimize electromagnetic interference (EMI) and ensure reliable operation. Components are strategically placed to reduce signal crosstalk, and proper grounding techniques are employed to prevent electrical noise from affecting the sensor signals. The traces on the PCB board are designed with appropriate widths and lengths to match the impedance requirements of the sensors and other components, further enhancing signal integrity.

Pressure sensor adapted PCB boards find applications in a wide range of industries. In the automotive sector, they are used in tire pressure monitoring systems, engine oil pressure sensors, and fuel pressure sensors. In industrial automation, these PCB boards are integrated with pressure sensors for process control, such as monitoring the pressure in pipelines, tanks, and hydraulic systems. Medical devices also utilize pressure sensor adapted PCB boards in applications like blood pressure monitors and respiratory pressure sensors. Overall, these specialized PCB boards play a vital role in enabling pressure sensors to function accurately and reliably, contributing to the performance and functionality of various systems and devices.