-

CN

-

Service Hotline

+8618129931046 Mr. Liao

• A-Level Supplier

• 20 Years Experience

• Process Monitoring

• MT Production Line: 7

• DIP Production line: 7

• Intelligent Management

• Automated Manufacturing

• Made in China

• Bulk Order Discount

• Customer Support

• 7*24 1v1 Service

• Technical Team

• Global Supply Chain

Shenzhen Chengchi Circuit Technology Co., Ltd. was established in 2014 and has been deeply involved in the industry for more than ten years. After years of market tempering and baptism, it has now developed into a one-stop service enterprise for PCBA OEM+ODM! The company's current service projects include PCB drilling blind holes, buried hole boards, and customized processing of double-sided boards with 4-38 layers of multi-layer circuit boards. We provide one-stop PCBA services and technical support for industrial control equipment PCBA, consumer PCBA, medical PCBA, new energy PCBA, automotive PCBA, smart furniture PCBA and other fields, including PCBA design, board modification, sampling and debugging, customized processing, PCBA outsourcing, high-end equipment circuit board maintenance, etc!

DetailWe Chengchi Circuit Technology have 15 years of experience in the PCBA industry and have become a leading PCB and PCBA manufacturer in China, providing one-stop PCBA 0EM and ODM services! We help our partners strictly control quality, shorten delivery times, and effectively control product costs. Our PCBA has a wide range of applications, such as automotive new energy, industrial equipment control, smart home, medical devices, consumer electronics, and other fields. As long as you trust us and become our partner, I will definitely give you a satisfactory answer!

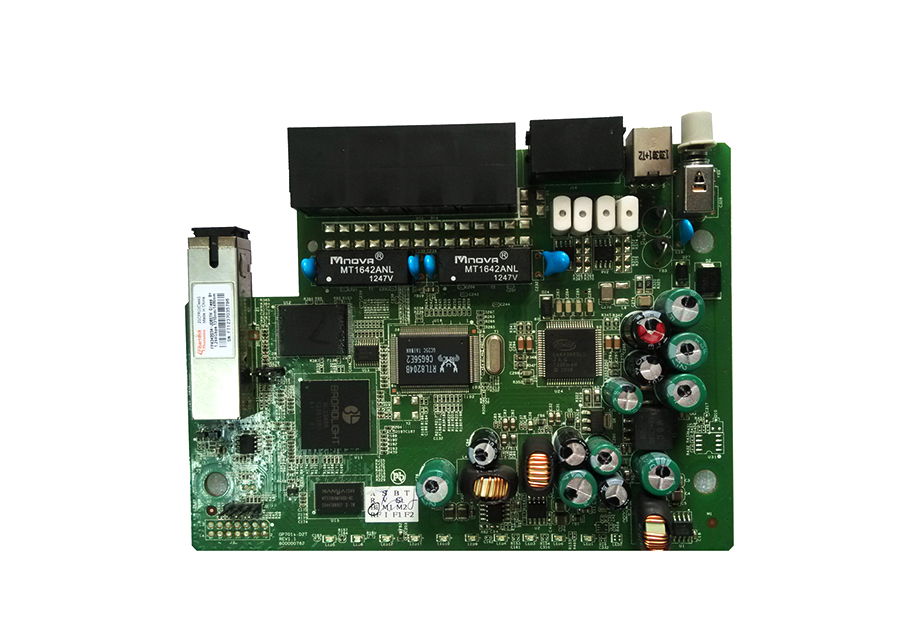

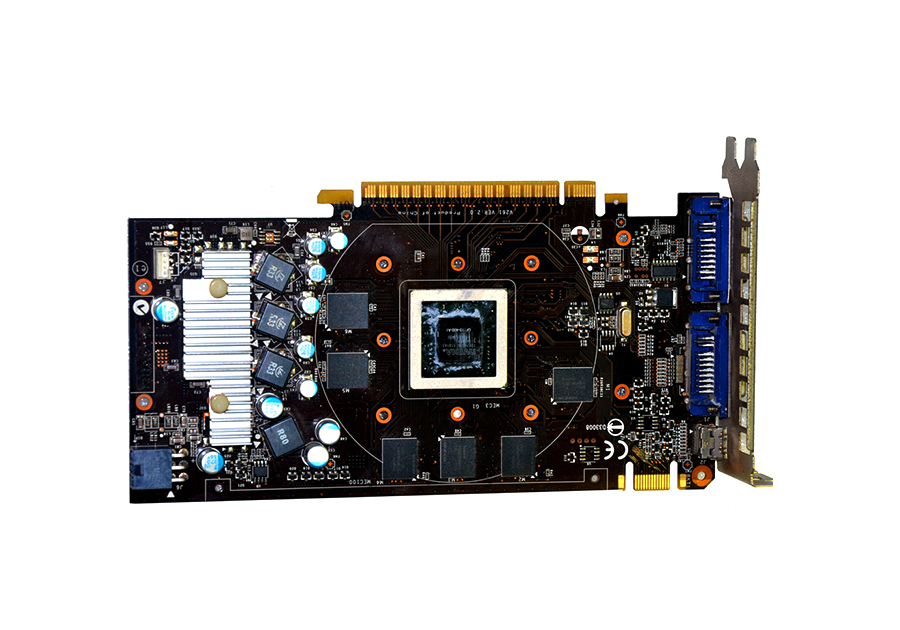

To meet the specific requirements of our customers in the field of electronic manufacturing, we are introducing customized PCBA (Printed Circuit Board Assembly) services. From circuit board design to component procurement, soldering, and testing, we provide a one-stop solution to ensure our customers' electronic products enter the market quickly and accurately.

To meet the specific requirements of our customers in the field of electronic manufacturing, we are introducing customized PCBA (Printed Circuit Board Assembly) services. From circuit board design to component procurement, soldering, and testing, we provide a one-stop solution to ensure our customers' electronic products enter the market quickly and accurately.

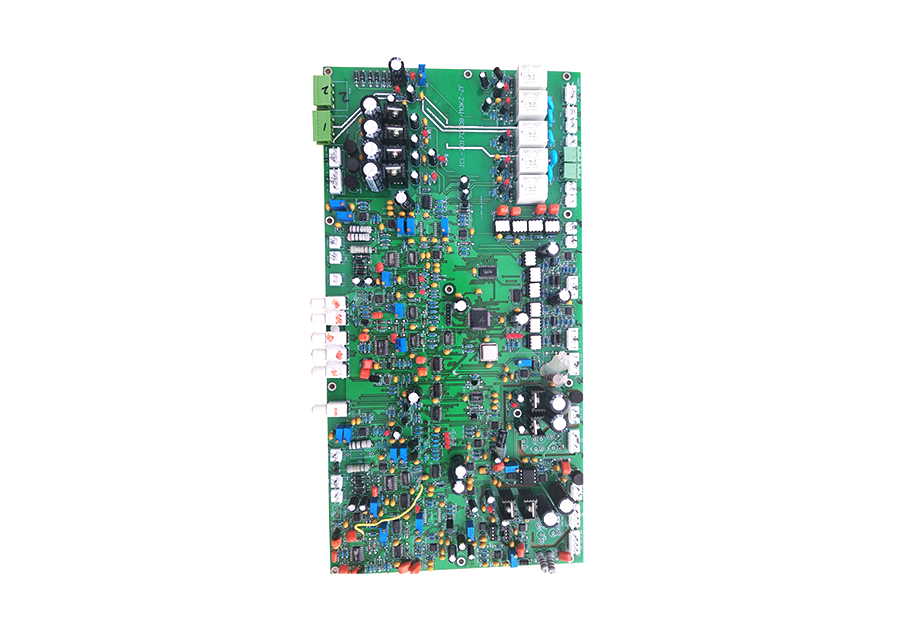

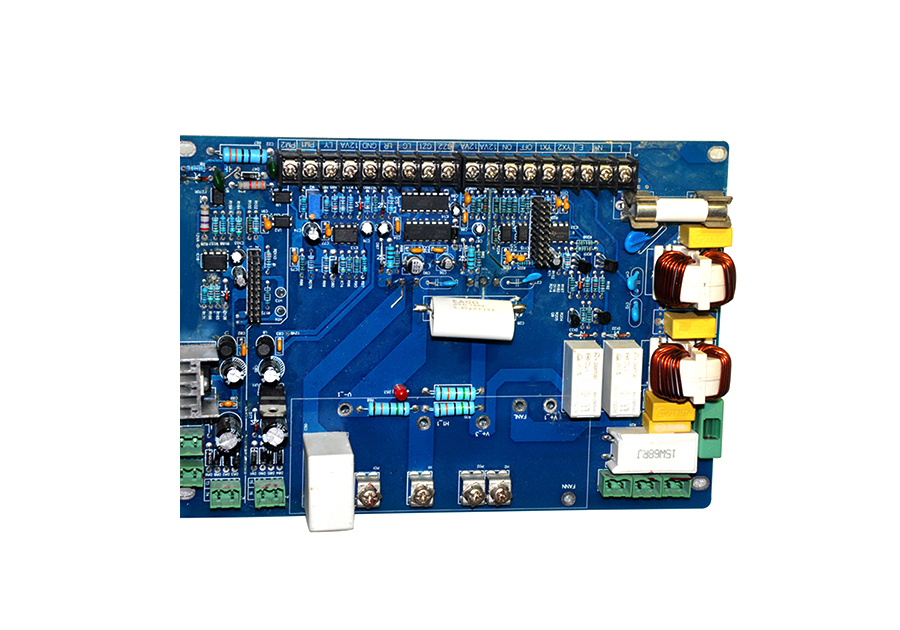

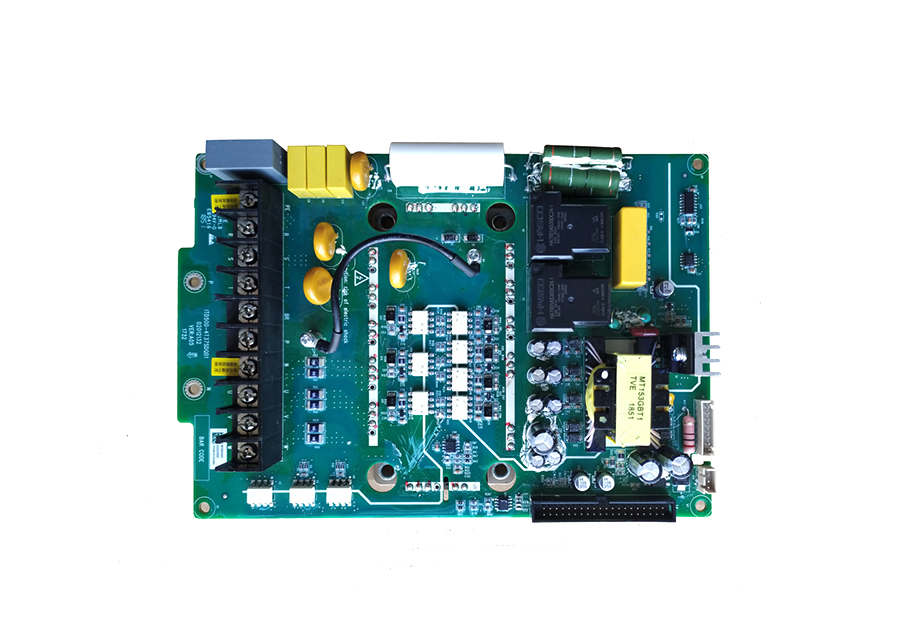

As the global energy transition accelerates, the field of new energy is thriving. New energy electronic products, as an integral part of this transition, are experiencing a growing demand for Printed Circuit Board Assembly (PCBA). In order to meet the PCBA requirements of clients in the new energy sector, we are introducing the New Energy PCBA Customization Service.

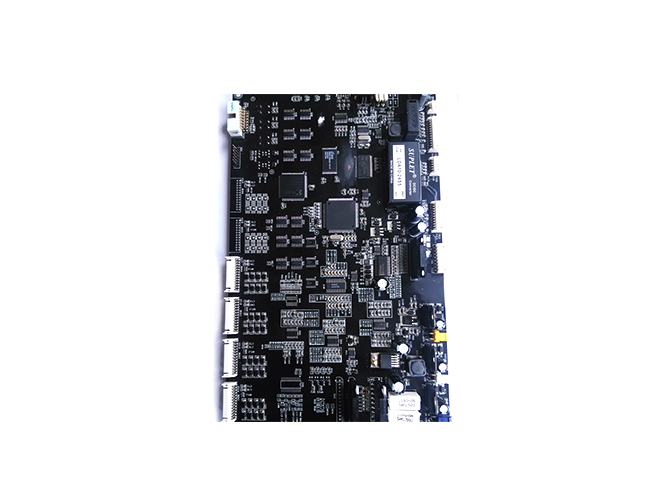

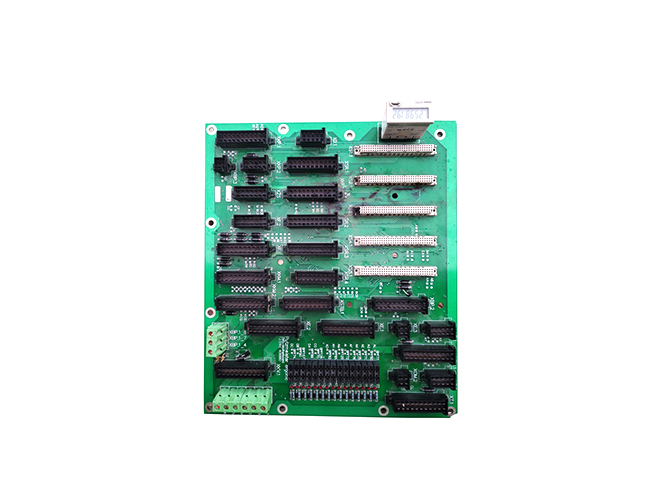

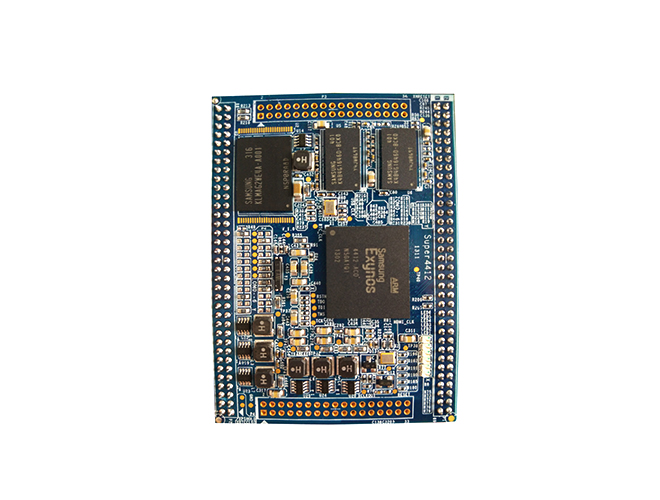

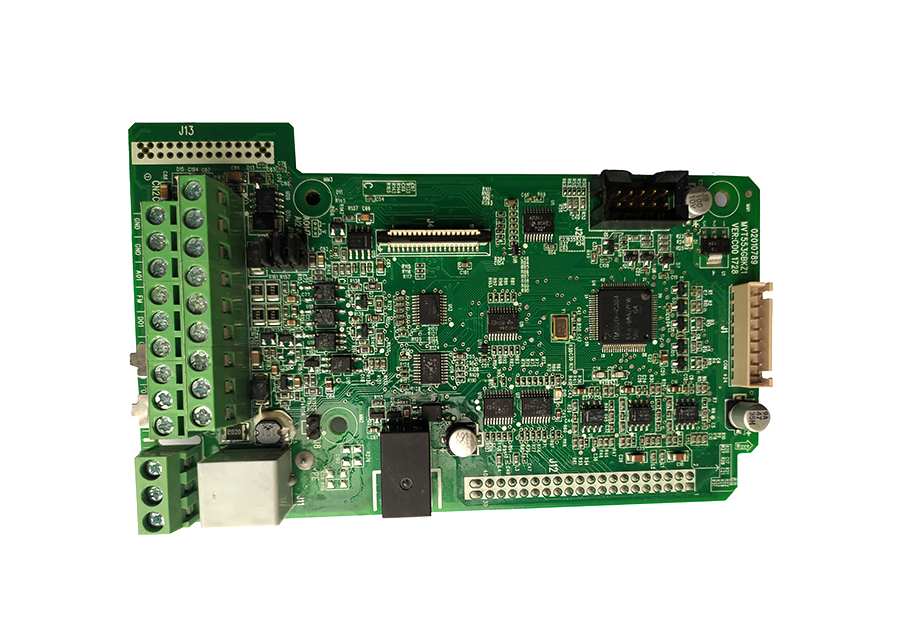

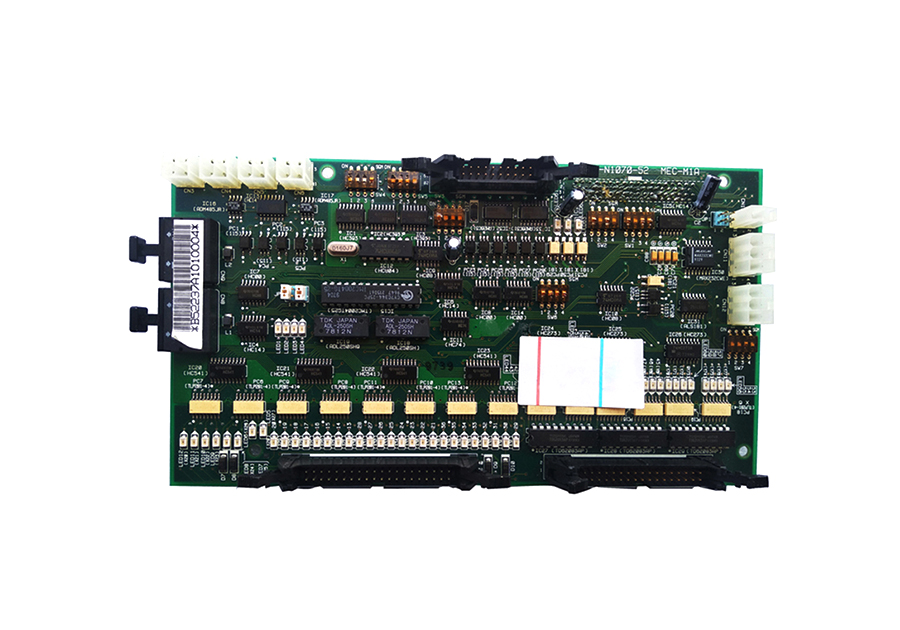

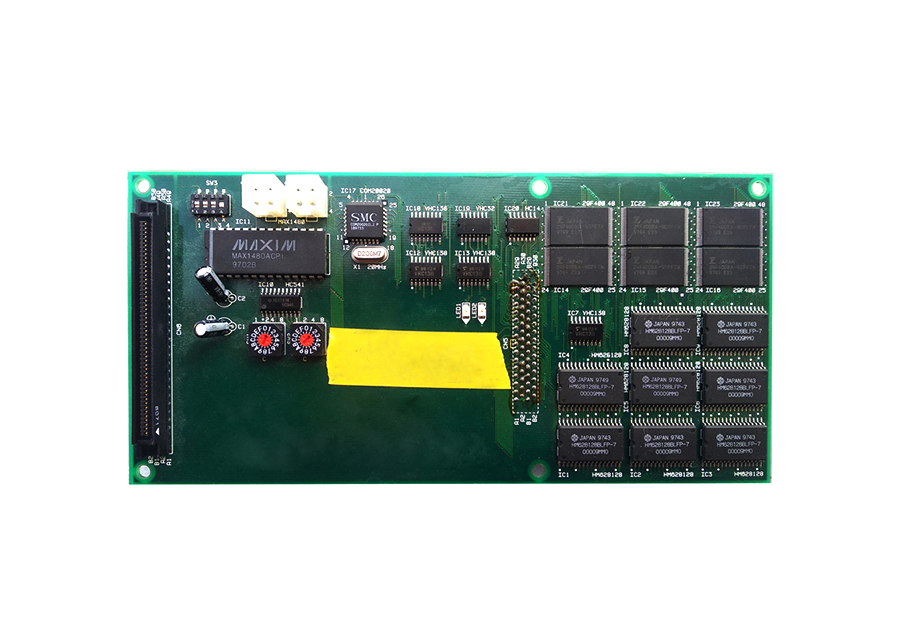

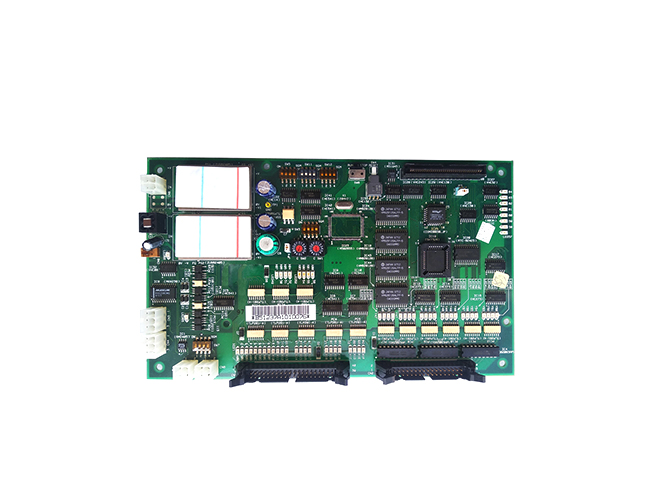

We are committed to providing high-quality customization services for industrial control board PCBA. Our goal is to ensure the satisfaction of our customers' specific requirements, delivering excellent product quality and outstanding technical support to guarantee their success in the field of industrial automation.

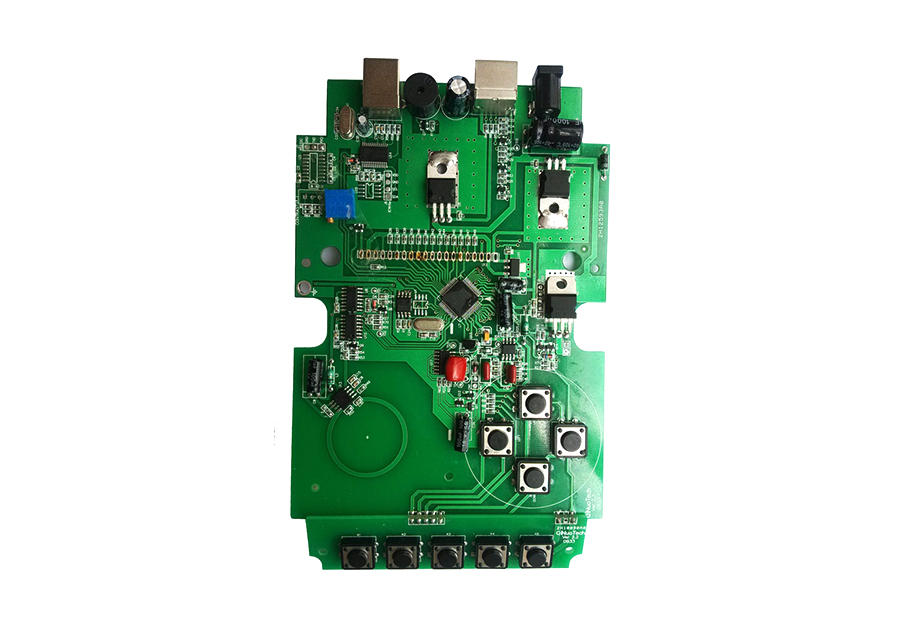

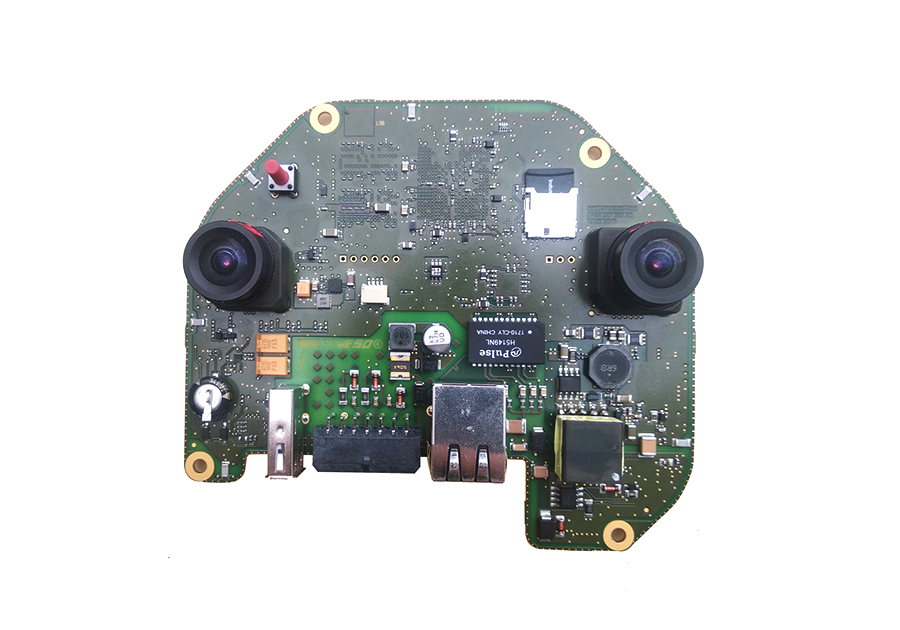

In the consumer electronics market, diversity and rapid innovation are key factors. To meet the diverse PCBA needs of consumer electronic products, we have introduced the Consumer Electronics PCBA Customization Service. This project aims to provide customers with a one-stop solution from circuit board design to production, ensuring rapid product launch and meeting market demands.

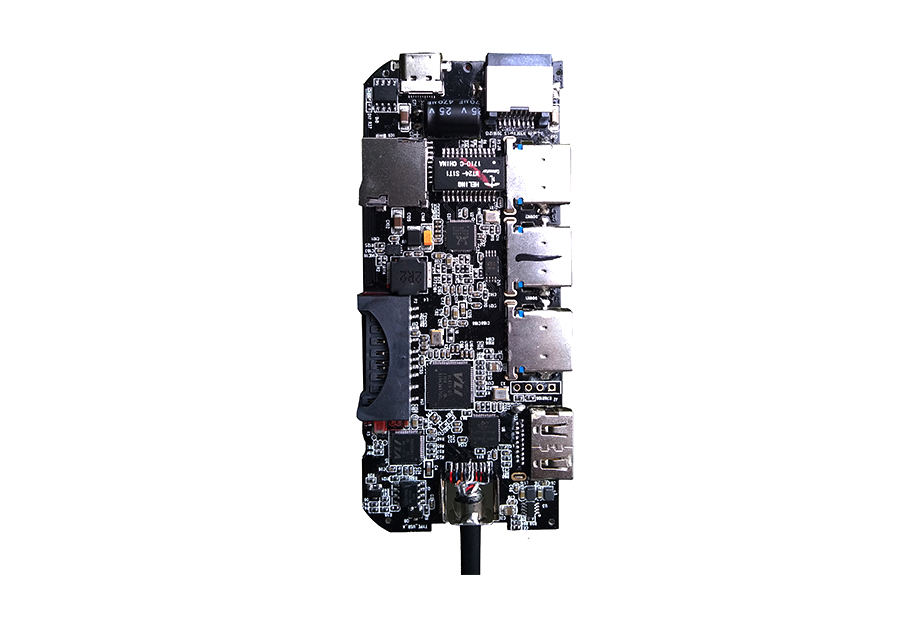

With the advancement of technology and the improvement of people's living standards, smart homes have become a new lifestyle trend. To meet the market demand for smart home products, we are introducing a comprehensive service project for Smart Home PCBA. This project aims to provide customers with a one-stop service for PCBA design, production, testing, and after-sales support.

This project focuses on providing customized, high-quality PCBA (Printed Circuit Board Assembly) services for medical devices. Combining advanced production technology, rigorous quality control, and comprehensive after-sales service, we are committed to offering a one-stop solution for medical device manufacturers, ensuring the stable, efficient, and safe operation of their equipment.

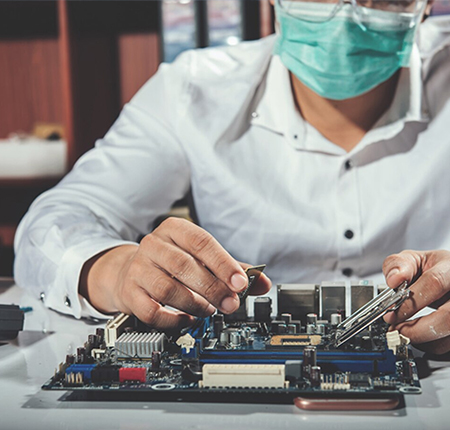

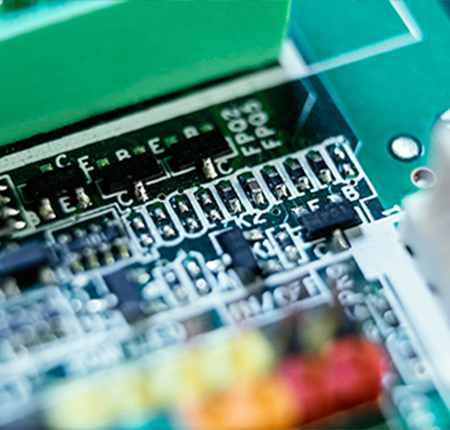

Our factory currently uses the industry's high-end equipment NPM-D3A high-speed surface mount machine to meet customer production capacity. To strengthen product quality management, we use fully automatic printing machines, SPI equipment, pre furnace AOI, post furnace AOI, and other equipment to reduce product defect rates.

Strictly control in accordance with IPC standards, international standards, and customer standards to ensure 100% qualified shipment rate;

Implement the quality PDCA cycle process to continuously improve product performance;

Own a full set of testing equipment including online AOI, X-ray, secondary element, impedance tester, halogen tester, ion contamination tester, hole inspection machine, coating measurement instrument, etc.

More than 200 professional and technical personnel with more than 10 years of PCB industry experience;

The number of layers can be double-sided to 32 layers, the minimum drilling hole is 0.1mm, the minimum line width and line spacing is 3/3mil. The thickest copper foil is 12oZ, and various special process PCBs can be produced;

It has a new and advanced fully automatic production line, such as automatic transportation of drilling holes, lamination of inner layer circuit solder mask characters and other processes, and is equipped with multiple high-end LDI exposure equipment, connected AOI, horizontal VCP line, automatic ET test, automatic appearance inspection machine and other high-end automation equipment

Full-process production process

First-line brand production equipment

Fast production cycle

Use ERP system control

Flexible to meet customer expedited order arrangement needs

An independent environmentally friendly wastewater treatment system

After-sales service 15 minutes fast response

Marketing service department one-to-one service

Customer service engineer timely door-to-door service, etc.